When the screw oil press machine works, the oil cake expelled is a very important indicator for the oil output rate. In order to achieve the optimal oil output rate, it is highly recommended to check the oil cake regularly when it in operation. (You may also be interested in Soybean Oil Production Line>>)

Normal Oil Cake: The normal cake produced by screw oil press should be in the form of a tile, smooth on the side of the screw axis, and a lot of scratch on the other side.

Abnormal Oil Cake: The cake is loose and weak, or the cake is not shaped. The color of the cake is deeper and it is made into pieces by hand.

Solutions for Abnormal Oil Cake

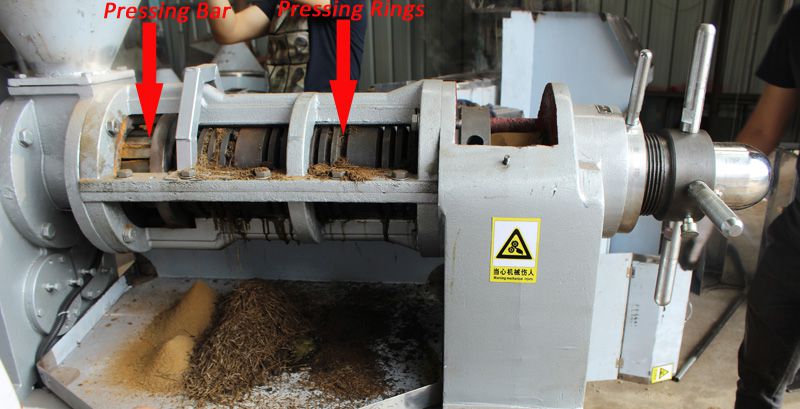

If the oil cake is loose and weak, or the cake is out of shape, the color is darker, it will be broken into pieces by hand. This shows that the raw material contains less water. So, adding proper water into the raw materials and mix it completely. If the oil press has a soft cake, a large flaky piece, or an increased oil foam, it means it has been added too much water. Under normal circumstances, there is no slag or very little slag between the pressing rings of spiral oil press, and slag is discharged at the pressing bars.

Thickness Reference of Common Oil-bearing Seeds

| Raw Material | Oil Cake Thickness (mm) | Raw Material | Oil Cake Thickness (mm) |

|---|---|---|---|

| Soybean | 0.8-1.5 | Rapeseeds | 1.0-1.5 |

| Sesame | 1.0-1.5 | Sunflower Seeds | 1.2-1.5 |

| Peanut | 0.8-2 | Cotton Seeds | 1.2-1.6 |

| Palm Kernel | 0.7-1.0 | Flaxseeds | 0.8-1.5 |

Correct Operation of Screw Oil Press

The position of oil flowing out of screw oil press is useful to check whether the moisture content of raw material is appropriate or not. When the moisture content in the press is too high or too low, the oil output position is shifted backwards. When the idling is normal, prepare about 50kg of rapeseed or soybeans ready for feeding into the hopper. Therefore, when the screw oil press begins to compress, the material feeding should be uniform and slow, so that the oil press can run in and out. Repeatedly and repeatedly for more than 3 to 4 hours, the temperature of the oil press gradually rises, and even smoke is emitted (this is a normal phenomenon).

Screw Oil Press Machine Types

When the oil squeezing is started, the temperature of the squeezing chamber is low and can be slowly twisted. The handle on the adjusting screw can be used to increases the thickness of the cake, and at the same time, increases the moisture content of the feeding material until the temperature of the pressing chamber is increased. When the temperature is up to about 90°C, After the normal operation of the oil press, the cake thickness can be adjusted to 1.5-2.5mm, and tighten the fastening nut.

ABC Machinery is professional manufacturer of oil press machine. We can provide the correct oil cake adjustment solutions to qucikly run your machine normally. In addition, we also provide installation and commissioning services for our customer, especially for complete oil pressing plant projects. If there are any questions about the operation, such as the oil cake adjustment, please contact us for technical solutions!

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)