Turnkey Project - 20TPD Semi-continuous Palm Kernel Oil Refinery & Fractionation Plant

- Project Site: Nigeria

- Production Capacity: 20 Tons Per Day

- Oil Refinery Type: Semi-continuous Oil Refining

- Main Section: Palm Kernel Oil Refining & Palm Kernel Oil Fractionation

- Raw Material: Crude Palm Kernel Oil (CPO)

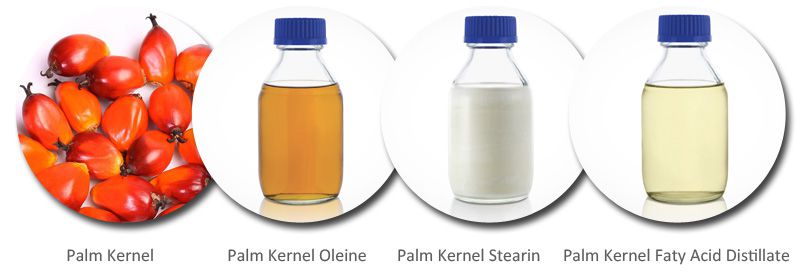

- End Product: Refined Palm Kernel Oil, RBD Palm Kernel Olein, Palm Kernel Stearin

- Main Palm Kernel Oil Refining Machine: Crude Oil Tank, Phosphoric Acid Tank, Crude Oil Heater, Acid Mixer, Alkali Mixer, Alkali Dosing Pump, Crystal Tank, Soapstock Tank, Oil-water Separating Box, Steam Jet Mixer, Liquid Cyclone, Drying Tower, Precision Filter, etc.

- Main Palm Kernel OilFractionation Machine: Crystallizing Tank, Water Cooled Screw Chiller, Membrane Filter Press, etc.

- Similar Project: 10TPD Soybean Oil Extraction and Refinery Plant in Nigeria; 10TPD Palm Oil Fractionation Plant in Cote D'Ivoire

ABC Machinery has been the leading oil processing machinery manufacturerer and supplier in China. And we have been in Nigeria market for many years. If you are interested in palm kernel oil production and unsure as to which palm kernel oil refining machine is best for your factory then you can consult our service team. Alternatively, we are always happy to offer technical help and advice and so if you require assistance then please do not hesitate to contact us.

Palm Kernel Oil Refining Plant Setup in Nigeria

This 20TPD Semi-continuous Palm Kernel Oil Refinery and Fractionation Plant Project was completed in 2019. It was ordered by a customer from Nigeria who has set up palm kernel oil milling plant. However, in order to produce high quality palm kernel oil to meet the increasing market demands, he decided to equip his palm kernel oil processing plant with palm kernel oil refinery and palm kernel fractionation machine. The palm kernel oil degumming and deacidification process is batch while the deodorization process is continuous. Fractionation process adopts PLC control. (You May Also Like: Mini Oil Refinery Plant Cost >>)

In the end, his palm kernel oil processing plant includes palm kernel oil extraction plant, palm kernel oil refining and fractionation plant, oil test lab, oil filling and packaging plant. In addition, he also built four crude oil tanks. Below details the onsite pictures of palm kernel oil refining machine installation. (Related Post: Palm Kernel Oil Extraction Machine Price in Nigeria >>)

The palm kernel refining machine developed and manufactured by ABC Machinery has unique and reasonable design, reliable performance, high degree of mechanization, high production efficiency, advanced technology and other characteristics. What's more, according to the requirements of users for palm kernel oil refining, various separate refining equipment can be combined together to form a series of automated production. If you are interested Palm Kernel Oil Processing Business in Nigeria and want to get the customized plan, please contact us for more detailed information.

Why Palm Kernel Oil Factory Needs Palm Kernel Oil Fractionation?

Fractionation is the special treatment of palm kernel oil. Palm Kernel Oi Fractionation is to cool the palm kernel oil to 45 ℃ or so and keep certain time, the composition of high melting point will be obtained by crystallization precipitation. The secondary filtering of fractionation will make palm kernel oil into three products of different melting points.

Palm Kernel Stearin: melting point higher than 40 ℃

Palm Kernel Soft Butter : melting point 30 ℃ around

Liquid Palm Kernel Oil: melting point below 20 ℃

The yield of these three products is approximately 20%, 30% and 50% respectively, among which the quality of liquid palm kernel oil can reach the standards of high quality cooking oil.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)