The oil obtained by pressing or extracting process is called crude oil. Most crude oil is went through initial filtration or sludge separation, but some are not. Even so, all the crude oil still contains some impurities. Unrefined crude oil contains free fatty acids (FFAs), phospholipid, carbohydrate, water, pigment and other impurities. The primary treatment of crude oil is gravity precipitation, filtration, centrifugation and other. The processed crude oil is being refined in crude oil refinery plant. ABC Machinery supply complete crude oil refinery plant for various crude oil, including tea seed oil, canola oil, peanut oil, corn germ oil, palm kernel oil, palm oil, etc. Beside, we are also great supplier of all scale crude oil refinery plant. If you have any extra requirements for oil pressing or crude oil refining, all the oil processing plants can be customized.

Customized Crude Oil Refinery Plant

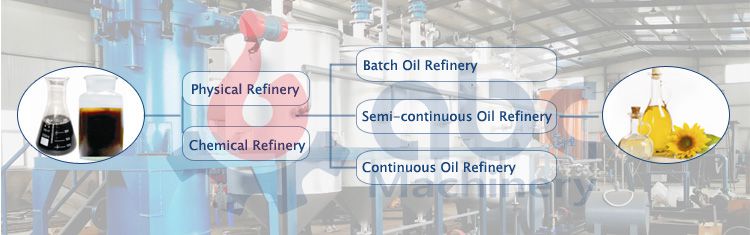

Crude Oil Refinery Plant Methods

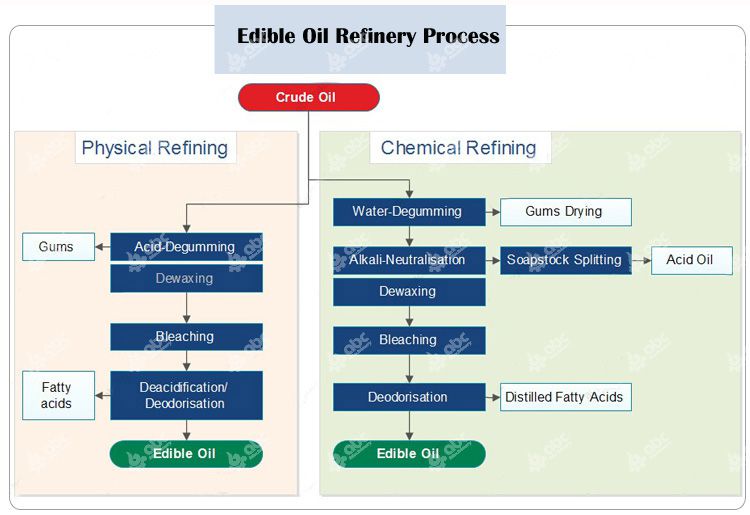

The purpose of crude oil refining is to make crude oil more suitable for human consumption by meeting the standards of colors, taste, smell and stability. The methods of crude oil refinery are chemical refining and physical refining. Chemical refining is to remove free fatty acids (FFAs), most phospholipids and other impurities in neutralizing processes by adding alkali. While, physical refining is to remove FFAs by steam stripping. The important benefit of physical refining is the high yield of oil, the reduction in the use of chemicals and water. Deciding to using chemical refining or physical refining method should take a lot of factors into account, such as the quality and acidity of the crude oil, the removal of soap feet, local environmental requirements and more.

Crude Oil Refinery Methods

Chemical Refinery Process: Degumming, Neutralizing, Decolorizing, Deodorization, Dewaxing or Winterization

Physical Refinery Process: Degumming, Decoloring, Deacidification & Deodorization

Crude Oil Refinery Plant Process

Degumming

The process of degumming is the removal of dissolved phospholipids and viscose substances from crude oil at the conditions of high temperature or low temperature so that they can be dissolved in water phase. High efficiency acid (phosphoric acid) can accelerate the process of degumming. Hydrated phospholipids can be removed with the added water (hydration degumming), and non-hydrated phospholipids are difficult to remove and can only be removed by using concentrated acid treatment to remove (acid degumming). Degummed water and acid are selected according to the variety of crude oil.

Neutralization

Neutralization is to add sodium hydroxide (NaOH) into degummed oil to make free fatty acids, lecithin and most of the pigment to form saponification and centrifugal separation, finally to remove acids. Generally speaking, the neutralization process consists of three steps, separation, washing of the soap and vacuum drying. The concentration of NaOH and the temperature of neutralization reaction were determined by properties of crude oil and initial free fatty acid content. The content of free fatty acid is high, and the concentration of sodium hydroxide is also high, so as to avoid the occurrence of emulsification. And a mixture of soap (foot) by centrifugal separator (primary centrifugal separation) off the crude oil, and then after rinsing centrifugal separation (secondary centrifugal separation) to remove water, finally by vacuum drying. Water washing mainly removes residual saponification from degummed oil. Vacuum drying removes the residual moisture in the oil after water is separated from water.

Dewaxing and Winterization

Dewaxing and winterization are used to remove a small amount of solid matter in the oil at freezing temperature. These solid substances are mainly saturated glycerides (stearin) or waxy (a small amount of fatty acids dissolved in fatty alcohols or oils). This process is mainly used for the refining of sunflower oil, corn oil and safflower oil, because they contain more wax than other edible oils (100 calories, 1000ppm). When handling this kind of oil to oil cooled down, slowly and at low temperature (5 ~ 10 ℃) to keep for a long time (at least 6 hours) for wax crystallization. To facilitate the crystallization and filtration, usually adding filter aid, 0.1% of the wax content, cooling can help promote the formation and stability of filtering crystal, filtering crystals grow and form good crystallization, so that ensure the stearic and wax is easier to be removed by filtration. Usually before the filter, the oil temperature rise to about 15-18 ℃ reduce oil viscosity filtration. Dewaxing can also be done alternately with a centrifuge. In this process, the neutralizing oil is cooled first and then enters the crystallizer, where the wax is gathered in the crystallizer. After a period of retention, the oil is pumped into the centrifuge for separation.

Decolorization

Decolorization mainly removes most of the pigments in crude oil, including colloids and trace amounts of saponification and other impurities. Under vacuum, 90-110 ℃, by adding suitable amount of bleaching clay mixing, can remove most materials that exist in crude oil. The amount of bleaching clay is roughly 0.8-2.0%, but all based on the quality of crude oil and refined oil. The bleaching clay in the oil is separated by a sealed vane filter. The filtered oil is then filtered by a polishing filter to remove trace amounts of bleaching clay particles in the oil after the first filtration. This step of polishing filtration is very important, because if the refined oils contain residual white particles, the oxidation stability of final oil products will be reduced. The residual oil content is usually about 20-40% in waste bleaching clay after filtration, which is the most important loss in oil refining process.

Deodorization

Deodorization is usually the last step crude oil refinery plant. Deodorizing section is mainly used to remove the odorous substances in oil under vacuum and high temperature through steam stripping. These smelly substances usually refer to aldehydes, ketones, peroxides, and other organic compounds. Deodorization can be seen as a multi-step process, mainly gas, heating, deacidification, deodorization and oil cooling. There are three main types of deodorization: intermittent, semi-continuous and continuous.

BEST Crude Oil Refinery Plant for Customers

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)