Rice bran oil is a nutritious oil beneficial to human health. However, due to the special characteristics of crude rice bran oil itself (high acid value and difficult to remove the color), the crude rice bran oil refining process technology is a more difficult type to deal with in the edible oil refining field.

ABC Machinery is a leader in the cooking oils processing industry, with experienced fats and oils engineers and professional edible oil mill plant designers, the company can help you solve the challenges of rice bran oil refining process and provide you with customized rice bran oil extraction and refinery solutions.

Start Profitable Rice Bran Oil Extraction and Refining Business

In this blog, we will take an in-depth look at rice bran oil refining process steps and rice bran oil refining equipment, exploring efficient and cost-effective solutions to help plant owners optimize their rice bran oil production process and help interested investors build a successful rice bran oil refinery plant. (Read More: How to start small cooking oil business>>)

Importance Of Rice Bran Oil Refining Process (Based on Extraction Techniques)

Rice bran oil is the oil extracted from rice bran which is peeled off from the epidermis of brown rice, and its oil content is about 16%~22%, mainly used for edible rice bran oil, rice bran oil soap and rice bran oil skin care beauty products.

When using mechanical pressing method to extract rice bran oil, the residual oil rate is high (6-7%), which means that a considerable part of the oil loss. In contrast, most rice bran oil mills prefer to use rice bran oil solvent extraction method for production, because the residual oil rate of this method can be reduced to less than 1%.

The leaching crude rice bran oil contains harmful solvent residues as well as waxes and other impurities of the rice bran oil itself, so it is necessary to pump the obtained rice bran crude oil into the physical refinery plant for further refining treatment.

| Main Components Of Crude Rice Bran Oil | ||||||

|---|---|---|---|---|---|---|

| Solid impurities/% | Phosphorus content/ (mg/kg) | Acid value/[mg(KOH)/g] | Moisture/% | Peroxide value/(mmol/kg) | Wax/% | Color (25.4mm groove) |

| 1 | 280 | 22 | 0.5 | 4.5 | 4 | Y50R9 |

Essential Steps in Rice Bran Oil Refining Process - Innovative Low-Cost Solutions

The own characteristic of crude rice bran oil decides the rice bran oil refining process different from other cooking oils.

► First of all, crude rice bran oil acid value is very high, generally in 8~20[mg(KOH)/g], some aging rice bran oil acid value is as high as 30mg (KOH)/g above;

► Secondly, contains wax 2%~5%, need to increase the dewaxing process;

► The color and luster are deeper, lead to decolorization difficulty.

Traditional alkali refining process has high lye loss and high refining cost. In order to produce qualified first grade refined rice bran oil, but also can reduce the cost, suitable for the use of rice bran oil physical refining process.

To overcome the challenges of rice bran oil refinery while minimizing costs, innovative solutions are imperative. Precise optimization of process parameters is essential to improve efficiency and reduce operating costs.

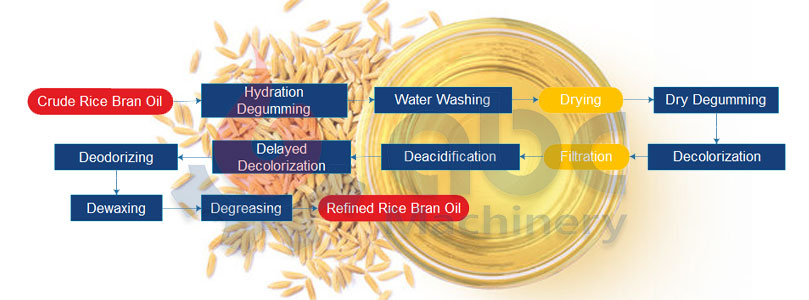

The rice bran oil refining process described in this paper has six main steps, namely, hydration and degumming, washing, drying and decolorization, deacidification, deodorization, and dewaxing. (The rice bran oil refining solution we design for our customers will be customized according to their actual situation, the following process is for reference only)

Crude Rice Bran Oil Physical Refining Process Flow

- 1. Hydration Degumming Process: Control phosphorus content to ≤30mg/kg

The key of physical refining of rice bran oil is to remove the colloidal substance in the oil as much as possible. First, heat the rice bran crude oil to 80~85 ℃, then add the 85% phosphoric acid (food grade), the amount of 0.3% of the oil volume. Stir quickly and then leave to settle to separate the degummed rice bran oil.

- 2. Water Washing Process: Remove water-soluble impurities from the rice bran oil and residual impurities from the previous step

- 3. Drying Process: Reduce the water content of rice bran oil to less than 0.5% for the next step

- 4. Dry Degumming Process: reduce phosphorus content in rice bran oil to ≤10mg/kg

- 5. Decolorization Process: decolorized rice bran oil with phosphorus content ≤5mg/kg, color Y35, R6 or so

The crude rice bran oil after dry degumming process is heated and sent to decolorizing tower, and the adsorbent white clay is added. The vacuum degree of the decolorizing tower is maintained at -0.09MPa, and the decolorizing time is 30 min. The recommended addition amount of white soil is 2% of the oil mass.

- 6. Distillation Deacidification Process: Physical refining, free fatty acid volatilization, condensation recovery

The decolorized crude rice bran oil is heated and enters the deacidification tower to contact with saturated steam. The flow time of oil in the tower is 5min, the amount of direct steam is 2%, and the vacuum absolute pressure is ≤200Pa.

- 7. Vacuum Deodorization Process: Saturated steam takes away the volatile odor substance in rice bran oil

The principle of deodorization is consistent with the above deacidification process. Oil flow time in the tower is 15~20min, deodorization temperature ≥230℃, direct steam dosage is about 1%, vacuum absolute pressure ≤200Pa.

- 8. Dewaxing Process: Low temperature crystallization removes wax in rice bran oil

After deodorization, the crude rice bran oil is slowly cooled down to 8℃ for crystallization, and the crystallization time is about 3 h. After that, it enters into the crystallization tank, and the crystallization is kept for 3 h under the condition of constant temperature and 8℃, and then it is filtered under the pressure of air of 0.6MPa, and then the dewaxed rice bran oil is obtained.

Is It Profitable to Invest in A Rice Bran Oil Refinery Plant?

The acid value and wax content of crude rice bran oil are high, resulting in a low yield of refined rice bran oil. However, it is calculated that the combined profit from refining and processing can be more than US$100 per ton of crude rice bran oil. High acid value indicates high purity of fatty acid, less splash oil and low rice bran oil refining loss. Compared with the traditional alkali refining process, the consumption of water, coal and electricity is reduced when the above physical refining process of rice bran oil is adopted. These factors show that investment in rice bran oil refinery plant is profitable.

In addition also need to pay attention to, because of the rice bran oil need to processed by solvent extraction method, rice bran oil processing plant scale to reach the daily processing capacity of more than 20 tons is most appropriate.

Professional Rice Bran Oil Refining Machines Recommended - From Reliable Manufacturer ABC Machienry

In the refinery process of rice bran oil, using efficient and reliable equipment is the key to ensure the quality of the oil. As a professional manufacturer of edible oil processing plant, ABC Machinery provides both small and large scale rice bran oil refinery plant to help customers realize efficient and energy-saving production.

In addition, we also provide complete cooking oil refining line solutions, from design to installation, to customize efficient and energy-saving production lines to help customers improve product quality and production efficiency.

Project List: Cooking oil extraction and refining plant setup in Zambia>>

1TPD Sunflower oil refining line in Tanzania>>

For more information about rice bran oil refining equipment, please visit our company website or contact our sales team. We are looking forward to cooperating with you!

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)