- Project Name: Iran Corn Germ Oil Processing and Refining Plant

- Location: Tehran, Iran

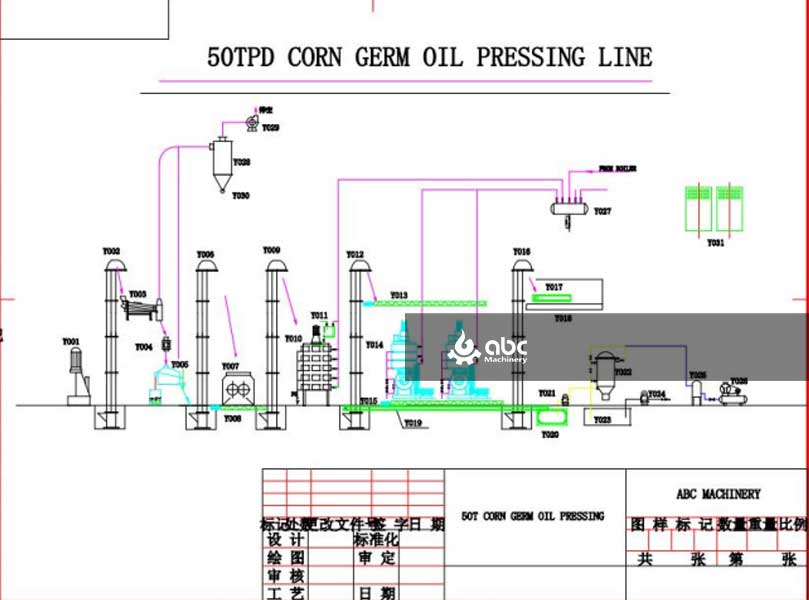

- Capacity: 50T/D Corn Oil Pressing Line & 15T/D Crude Oil Refinery Line

- Process: Edible Oil Hot Pressing Process Technology & Oil Refinery Process

- Reference Price: USD 30,0000

Start A Profitable Corn Oil Exatrction and Refinery Business in Iran

50T/D Corn Oil Processing Plant Constructed Successfully in Iran

The client of this corn oil manufacturing and refinery project is a large corn flour wet milling plant in Iran, and the raw material corn germ is a by-product of the factory. In order to make full use of these processing residues, expand business channels and increase economic returns, the Iranian customer decided to invest in building this corn oil processing plant.

Through market research and thorough communication, the customer finally purchased the new corn oil extraction machines and edible oil refining machines from ABC Machinery. After the completion of the new project, the annual production capacity of corn oil plant will reach 600,000 tons, and the by-product of the original plant, corn germ, will bring additional economic benefits.

Iranian Client’s Corn Processing Factory

Group Photo of ABC‘s Engineers and Iranian Workers

Since receiving this project, ABC Machinery has fully considered the customer's needs and provided one-stop corn germ oil factory solutions from the customer's point of view.

Including the plant layout design and equipment layout drawing design, machine and equipment manufacturing and purchasing, inspection and delivery, sending engineers to Iran to supervise the installation and debugging, and training the local staff to operate the equipment. Finally, we successfully completed the project and achieved a win-win cooperation between us and the customer.

Witness the Realization of Iran's Corn Oil Plant Project Step by Step

Corn Oil Processing Factory and Production Line Design

Corn Germ Oil Plant Equipment Ship to Iran

Iran Corn Oil Project Onsite Installation

Corn Oil Pressing Line Was Completed

Corn Oil Refining Line Was Completed

Machines test run and finished Corn Germ Oil Display

Equipment List of The Iran Corn Oil Production Line Project

The equipment list for this 50 t/d hot pressing corn oil extraction plant and 15 t/d batch corn germ oil refinery plant in Iran project is shown in the table below:

| 50TPD CORN OIL PRESSING LINE | |||

|---|---|---|---|

| Number | Name of Machinery | Model | QTY |

| 1 |

Feeding pot

|

WLG120

|

1 |

| 2 |

Magnetic separator

|

TCXT20

|

1 |

| 3 |

Destoner

|

TQSF100

|

1 |

| 4 |

Steam cooker

|

YZCL200*5

|

1 |

| 5 |

ZY26

|

2 | |

| ...... | |||

|

15T/D CRON OIL REFINERY PLANT

|

|||

|---|---|---|---|

| Number | Name of Machinery | Model | QTY |

| 1 |

Oil refining tank

|

LYYG·180*350

|

2 |

| 2 |

Bleaching tank

|

LYYG·180*350

|

1 |

| 3 |

Hot water tank

|

XRS200*100*7

5

|

1 |

| 4 |

Vibrating filter

|

ZDL15

|

1 |

| 5 |

Deodorizing tank

|

TXQ200*350

|

1 |

| ...... | |||

The above partial list of equipment is for reference only. Know more information and price of our edible oil processing machines and cooking oil refining machines, please contact us!

Innovative Corn Oil Extraction and refinery Process Technology for The Project Success

Based on the customer's raw material and final product requirements, ABC Machinery‘s engineers custom-designed a 50-ton per day corn oil pressing process and a 15-ton per day corn oil refining process.

The 50 Tons/Day Corn Oil Extraction Process

Corn oil pressing technology utilizes state-of-the-art oil hot pressing process technology to ensure that our customers receive the highest quality corn oil and oil cake by-products.

- Ⅰ. Corn Germ Cleaning Process

The original corn grinding plant output of corn germ through the raw material cleaning equipment (vibrating sieve, de-stoning machine, magnetic separator), to remove all kinds of impurities in the corn germ.

- Ⅱ. Corn Germ Rolling and Steam Frying Process

The cleaned corn germ is rolled and steamed to increase the oil yield.

- Ⅲ. Corn Oil Pressing Process

The pre-treated raw materials are fed into two large oil presses. The oil press machines are equipped with a frying pan on the top to keep the temperature of the material maintained at about 110-120℃.

The oil cake is collected and the corn oil enters the filtering machine. Finally, it enters the crude oil tank and waits for the next step of refining.

The 15 Tons/Day Crude Corn Oil Refinery Process

- Ⅰ. Degumming &Neutralization Process

Crude corn oil into the refining pot, slow speed stirring to warm up to 60℃. Add lye to the refining pot and stir slowly for 10-20 minutes to start settling for 4-6 hours. Finally, open the valve under the refining pot to drain the soap horn until the oil comes out and close the valve.

- Ⅱ. Bleaching Process

The corn oil in the refining pot is sucked into the decolorization tank by vacuum. Stirring raises the temperature to 105-110℃ to evaporate the water. Subsequently, white clay (3%-5%) is added, stirred, and when finished, cooled down to 80℃ for the next process.

- Ⅲ. Deodorization Process

The oil from the decolorized oil tank enters the deodorization tank, warms up to 220-260℃, and vacuums for 4-6 hours; the odor is taken away with the negative pressure vacuum unit. The deodorization tank is cooled down to 80℃, and the finished oil is discharged to get the refined corn oil.

[Quality and Service Guarantee of ABC Machinery]

- Ensure one-time installation and debugging check and acceptance.

- Provide products with good quality, advanced skills, and reasonable prices.

- Offer free operator training to ensure independent operation.

- Assign 2 technicians for on-site control during installation.

- Appoint a project manager and skilled team for installation and debugging.

- Conduct separate and group equipment debugging after installation to ensure trouble-free operation under full load. Provide comprehensive report data and documents upon completion.

- During the guarantee period, provide free maintenance or replacement for equipment damaged due to product quality issues. For damages caused by worker error, only charge for broken parts.

- Offer solutions within 6 hours of problem notification.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)