Thinking About Starting a Palm Oil Business in Nigeria? 3 Investor Profiles

Starting a palm oil production business in Nigeria is not as simple as “seeing a market opportunity.” In recent years, the Nigerian government has identified palm oil as a priority crop under its agricultural revitalization agenda, encouraging local oil processing to reduce imports. However, whether this is a suitable venture depends heavily on your own resources and capacity.

ABC Machinery: Reliable Palm Oil Processing Machine Manufecturer

- Small-scale investors: If you only have $10,000–$20,000, it’s best to start with a mini palm oil milling unit (about 1–2 tons/day).

Purchase a set of basic equipment, including a palm oil press machine, palm fruit fermentation tank, fruit stripper, and oil filter. Set up a simple processing workshop in rural areas. This setup is ideal if you own land, have a stable raw material source, and are close to your sales market. It is especially common in southern producing regions.

However, it comes with limitations in palm oil production capacity and oil quality, making it difficult to access high-end markets.

- Local traders ($30,000–$100,000, processing 5–10 tons of palm fruit per day): If you already have access to palm fruit suppliers or edible oil sales experience, you can step into the palm oil processing steps.

With high import tariffs in place, locally extracted oil has a cost advantage. At this stage, the key is controlling production efficiency and minimizing raw material loss. Instead of high-end machines, prioritize smooth palm oil mill process workflow and efficient operations.

- External investment teams: With a budget over $100,000, you can build a standardized small palm oil mill plant or even a more industrialized factory.

This involves construction, palm oil production line, red palm oil refining and fractionation stages. However, such a project goes beyond money—it requires land, electricity, personnel, and logistics planning. Don’t treat this as just an equipment purchase—you need a “feasible palm oil business plan” first.

Whether you are a small investor or planning to set up a standardised mill, launching a palm oil business is more than just buying equipment - ABC Machinery is your one-stop shop for project planning, equipment selection and investment appraisal, so contact us for a tailored solution!

Palm Oil and Palm Kernel Oil Have Different Processes and Machines

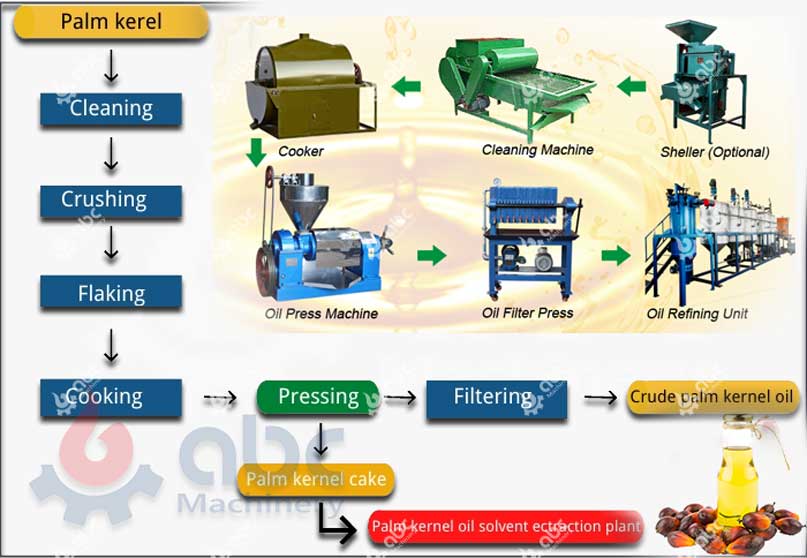

Besides the common palm fruit oil, palm kernel oil is another valuable product with its own processing route. (Read More: Start Palm kernel oil business plan>>)The palm kernel oil processing steps and equipment are similar to those for general oilseeds oil extraction, sunflower seed oil, groundnut oil, etc.

Processing Steps and Equipment for Palm Kernel Oil

| Step | Equipment | Function |

|---|---|---|

| 1. Kernel grading | Vibrating screen | Grades kernels by size for efficient separation |

| 2. Shell separation | Kernel sheller | Splits kernel shells from nuts |

| 3. Wind separation | Air separator | Uses airflow to separate light shells from heavier kernels |

| 4. Kernel crushing | Crusher | Reduces kernel size for better oil extraction |

| 5. Kernel roasting | Rotary roaster | Optimizes temperature and moisture for maximum yield |

| 6. Oil extraction | Palm kernel oil expeller machine | Physically presses out oil |

| 7. Oil filtration | Frame filter machine | Removes solids and ensures oil quality |

Palm kernel oil is high in value and ideal for high-end markets such as cosmetics, pharmaceuticals, and premium food. Although the oil yield is lower, its market price is higher, making it a high-margin product.

Small Palm Kernel Oil Extraction Process and Equipment for Sale

Additionally, by-products such as palm shells and palm fiber residues can be converted into biomass fuel, animal feed, soil conditioners, or biodegradable plastic materials—offering new income streams and aligning with tightening environmental regulations.

Palm Oil Milling Made Simple: Guide from Raw Materials to Equipment

For investors planning to launch a palm oil production business in Nigeria, every stage—from raw material sourcing to equipment configuration—has a direct impact on profitability and cost control.

Palm Fruit Supply Chain in Nigeria and Procurement Strategies

Securing a steady source of palm fruit is the first step in launching a profitable palm oil production business in Nigeria. Although the country has abundant palm resources, its supply chain has certain characteristics.

Nigeria has approximately 2.5 million hectares of oil palm plantations, but over 80% are operated by smallholders with outdated processing capacity, leading to premature sales of unprocessed fresh fruit bunches (FFBs).

- Direct contracts with farmers: Set up collection points and make seasonal purchases. Suitable for businesses with strong cash flow.

- Procurement via cooperatives: Collaborate with local farming cooperatives for stable mid-scale supply.

- Self-established plantations: A long-term strategy for those with land, offering better quality control but requiring larger initial investment.

According to Nigeria’s Ministry of Agriculture, the total palm fruit yield in 2023 was around 11 million tons, but only about 60% was processed—highlighting a clear market gap for new factories.

Complete Equipment Setup for Palm Oil Pressing and Refining

Once raw materials are secured, the next step is building an efficient palm oil processing line to extract oil from the palm fruit. The palm oil production process is typically divided into two key stages: palm oil pressing (crude oil extraction) and refining (quality improvement). The equipment setup in each stage affects capacity, oil quality, and investment cost.

1. Pressing Stage: From Palm Fruit to Crude Palm Oil

Speed is crucial in pressing FFBs to avoid spoilage.

| Process | Equipment | Description |

|---|---|---|

| Fruit bunch stripping | Palm fruit thresher | Separates palm fruits from bunches |

| Digesting treatment | Palm fruit digester | Softens fruit, boosts oil yield |

| Oil extraction | Screw oil press machine | Extracts crude palm oil |

| Oil clarification | Oil filter machine | Removes fibers and impurities for clearer oil |

Purchase Small Medium Plam Oil Milling and Refining Plant at Factory Price

2. Refining Stage: Improve Oil Quality to Meet Edible Standards

Crude palm oil contains many impurities and free fatty acids. Oil refining plant is needed for higher-grade edible or exportable oil.

| Process | Equipment | Objective |

|---|---|---|

| Degumming | Degumming tank | Removes phospholipids and gums |

| Neutralization | Vacuum neutralizer | Reduces free fatty acid content |

| Decolorization | Bleaching tower | Enhances oil color and clarity |

| Deodorization | Deodorizing tower | Eliminates odors and improves shelf life |

Practical tip: Start with only the palm oil pressing plant if funds are limited, and upgrade with a palm oil refining unit later.

As a trusted manufacturer of palm oil processing equipment, ABC Machinery offers complete turnkey solutions for small- to large-scale palm oil production.

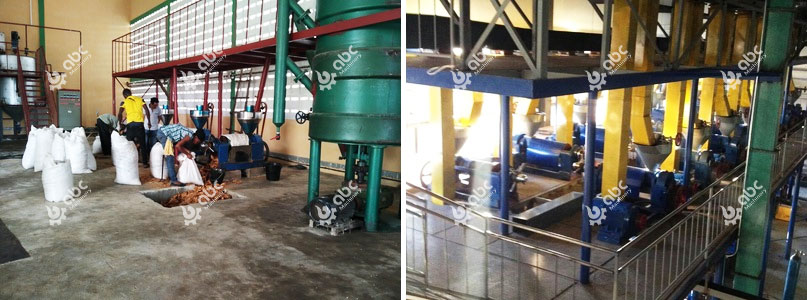

Inside Palm Oil Factory Projects in Nigeria from Planning to Production

We have successfully implemented multiple palm oil production projects in Nigeria, offering clients full support from planning to commissioning. Our expert solutions and reliable equipment ensure timely delivery and smooth operation—contributing to local economic development.

Cooking Oil Production Plant Project Building in Africa

| Project Name | Raw Material | Capacity |

|---|---|---|

| Palm Fruit Oil Press Line | Fresh palm fruit | 1TPH |

| Palm Fruit Extraction Plant | Fresh palm fruit | 20TPD |

| Complete Palm Oil Factory | Fresh palm fruit + palm kernels | 10TPD palm fruit pressing + 10TPD palm kernel oil pressing + 3TPD refining line |

If you are interested in our palm oil production business or have any questions, feel free to contact us. Our team will offer professional consultation to help you achieve your goals.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)