In recent years, Nigeria has attracted a growing number of investors interested in its edible oil processing sector, particularly soybean oil. However, turning an investment intention into a fully operational soybean oil production plant is far more complex than expected. Questions such as “Is there enough raw material? Can the setup process proceed smoothly? What equipment is suitable?” must be answered.

Provide Complete Services for Your Soybean Oil Mill Business

This article offers a frontline perspective—from raw material assurance and regulatory barriers to equipment selection and investment risks—to help you systematically understand the key steps and feasibility of building a soybean oil production plant in Nigeria.

Does Soybean Oil Production Make Sense in Nigeria?

Many clients seeking to enter Africa’s agricultural processing sector often consider Nigeria as their first stop. But “suitability” doesn’t always translate to a project being successfully established. It’s not just about the size of the Nigerian soybean oil market; what matters more is whether a soybean oil mill plant can evolve from a blueprint to a functioning facility.

Is There a Stable Source of Soybeans?

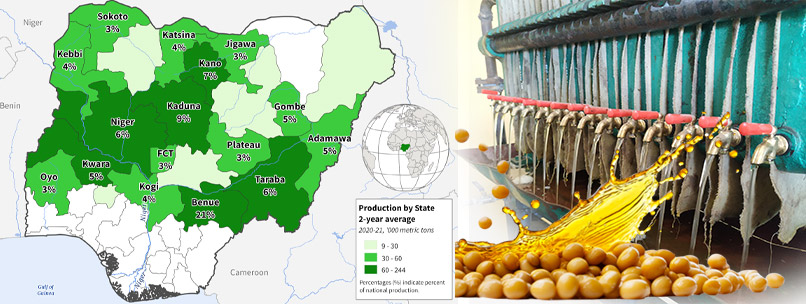

Soybean production in Nigeria has seen steady growth. According to FAO data, in 2023 Nigeria produced around 1.25 million tons of soybeans, primarily in agricultural states like Kaduna and Benue in the central-north region. This alone indicates that soybean raw materials are fundamentally secured, provided the factory is strategically located.

If your goal is to build a medium-sized soybean oil processing plant that refines 20,000 tons of oil annually, relying solely on local farmers may bring seasonal fluctuations or procurement challenges. Investors often use the following strategies to ensure raw material stability:

- Contract Farming with Local Farmers: Through cooperatives, but this requires attention to contract enforcement and prepayment risks.

- Import from Neighboring Countries: Such as Niger and Benin. With overland distances under 500 km, transport costs range from $40–60 per ton.

- Establish Own Farms: Ideal for long-term and large-scale plans. Land is often leased from state governments for 25–50 years.

Choosing a site near production zones but far from consumption markets results in high transportation costs for finished oil. Conversely, locating close to large cities like Lagos while far from soybean fields can mean competing for expensive raw materials. The best locations are usually in the central-southern belt of Nigeria, offering balanced access to both ends.

To properly launch a soybean oil plant, start with two actions:

(1) Conduct on-site investigations in at least 3 potential areas, gathering data on farming scale, price trends, and seasonal cycles;

(2) Reach out to state governments or farming cooperatives for potential land incentives or supply agreements.

Soybean Production Condition in Nigeria

What You Might Miss Before Launching Your Soya Oil Plant

Many investors only see Nigeria’s large population, high oil prices, and big market potential, but overlook basic oil mill plant setup challenges:

- Land Acquisition Procedures: Land registry is not standardized. Purchase often requires negotiations with local chiefs and state officials. Secure legal land titles in advance.

- Power and Water Supply: Nigeria averages less than 5 hours of electricity per day. 95% of factories need backup generators. Many rely on boreholes with purification systems.

- Forex Restrictions: Severe dollar shortages mean the Central Bank frequently restricts fund transfers. Set up offshore accounts under your project company for trade settlements.

- Port and Logistics Efficiency: Lagos Port is heavily congested; customs clearance may take 3–6 weeks. Some investors turn to inland ports or specialized logistics.

- Policy Compliance and Localism: Some states impose unofficial “double approvals” or “extra fees.” You’ll need a local consultant experienced in navigating these issues.

Organize a site visit, covering at least two farming areas and one industrial site. Find a local partner or advisor familiar with land, utilities, and customs procedures to assess the ground realities.

Choosing the Right Soybean Oil Machines Based on Plant Size

To build a soybean oil plant in Nigeria, your first step should be to clarify your output goals and profit model.

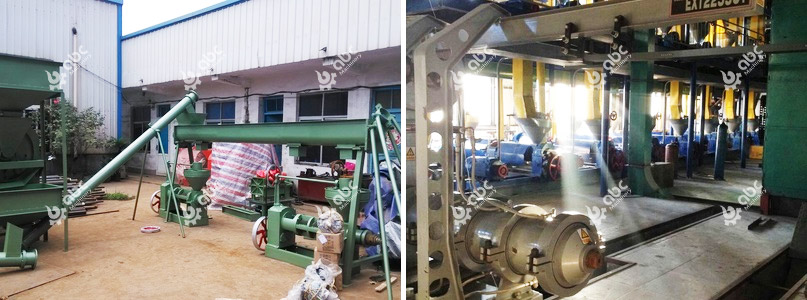

ABC Machinery has supported a wide range of clients—from small community edible oil mills producing a few hundred tons per year, to industrial oil mill plants exceeding 100 tons per day. Experience shows: don’t blindly aim for high capacity or premium setups. Instead, base decisions on your actual investment capacity.

Here are three typical soybean oil manufacturing equipment setups with their corresponding scales:

| Type | Daily Capacity (Raw Soybeans) | Target Users | Core Equipment Configuration | Estimated Investment |

|---|---|---|---|---|

| Mini soybean oil mills | 1–5 tons | Home users/small workshops | Cleaning equipment + cooker + 1-2 small screw oil press machines + simple oil filter | $8,000–$20,000 |

| Medium Commercial soya oil plant | 10–30 tons | Agri-traders/Cooperatives | Cleaning machine, soybean oil extruder machine+ cooking machine + medium/large screw oil press + filtering + small oil refining system | $50,000–$120,000 |

| Large soybean oil processing Plant | 50–100 tons | Foreign companies/Industrial parks | Full continuous pre-treatment line + continuous pressing + solvent extraction (optional) + continuous refining + oil tanks + bottling line | $250,000+ |

Related Posts: Soybean Oil Extraction Process Guide>>

Soybean Oil Refing Process and Machines>>

If you’re still unsure which setup fits, send us your annual output target, raw material supply plan, and budget. We’ll provide a customized equipment recommendation with a layout diagram and soybean production plant business plan.

ABC Machinery’s Global Success in Soybean Oil Processing Projects

ABC Machinery has helped numerous clients successfully launch soybean oil production lines in various countries. We offer end-to-end services, from equipment supply to installation and commissioning, tailored for local conditions and inclusive of operator training. This ensures smooth startup and reliable long-term operations.

Small, Large Soybean Oil Processing Plant Project Report

What You Must Solve Before Your Factory Can Operate Smoothly

Many clients initially believe factory setup only requires “buying equipment + acquiring land”. However, real challenges revolve around supporting systems: permits, infrastructure, manpower, and operations. (You may be interested: Cost of start a small soya oil processing plant in Africa>>)

Here are essential issues to consider when building a soybean oil production plant in Nigeria:

1. Company Registration and Banking Setup

A legal company is mandatory for equipment purchases, import/export payments, and wage disbursement. Nigerian company registration takes 2–4 weeks. Register as a Limited Liability Company for better access to bank accounts and compliance.

2. Land and Construction Permits

In industrial zones like Lagos or Kaduna, land is often leased or allocated by the government. For privately owned land, you must apply for land use conversion and building permits. Incomplete procedures may lead to project suspension.

3. Utility Infrastructure: Electricity, Water, Waste

Even the best equipment won’t run properly without reliable electricity and clean water. Refining stages demand steady power and steam. Plan for energy needs in advance. Consider solar, battery storage, or diesel generators.

4. Labor Organization and Training

Labor is affordable in Nigeria but lacks mechanical experience. Suggested steps:

- Request the equipment supplier to send engineers for installation and training.

- Train 1–2 core local employees for maintenance roles.

- Set up standard operation procedures (SOPs) and emergency shutdown protocols.

We provide equipment setup and on-site training services.

5. Export Permits, Packaging, and Sales Channels

If you plan to export soybean oil to other African or Middle Eastern markets, you must obtain export licenses, inspection certificates, and label approvals. Packaging should suit the target market’s language and size preferences (1L/5L plastic bottles, 20L drums).

Common Pitfalls in Soybean Oil Extraction Machine Purchase

Many clients fall into two traps: focusing solely on soybean oil extractor price over suitability, and ignoring post-sale support. In countries like Nigeria with weak infrastructure, poor soybean oil making machine choices can cripple your factory.

Small Soya Oil Production Line and Extraction Process Flow Chart

❌ Mistake 1: Equipment Parameters Don’t Match Local Soybeans

Chinese-made oil press machines are calibrated for Chinese soybeans. Nigerian soybeans tend to have higher moisture and impurities, sometimes even wild or insect-damaged seeds. Without adjustment, oil yield drops and equipment wears out faster.

✅ Tip: Ask suppliers for test results with Nigerian samples or send samples for testing in China ABC Machinery.

❌ Mistake 2: Overcapacity Lowers Efficiency

One client imported a set of 80-ton-per-day machines. On arrival, they found raw materials were insufficient and electricity was unstable. The result: low utilization, high unit energy cost, and financial losses.

✅ Tip: Choose a modular setup with mid-size capacity and scalable design. Expand gradually based on seasons and demand.

❌ Mistake 3: Ignoring Voltage and Spare Part Compatibility

Nigeria uses 3-phase 415V/50Hz power, but some equipment defaults to 380V. Adapters are possible but raise risk. Also, can spare parts (motors, filters, seals) be sourced locally?

✅ Tip: Request a full spare parts list and replacement schedule. Consider bundling spare parts with your equipment order.

Local Regulations, Import Duties, and Customs Tips for Nigeria

Many first-time buyers overlook customs clearance and regulatory issues. Equipment may arrive at port but remain stuck for weeks.

-

Can You Get Import Duty Waivers?

Some agricultural machinery is duty-exempt. But the process is complex and requires submitting project files and equipment lists to the Ministry of Agriculture. Budget assuming standard tax rates. -

How Long Does Customs Take?

Normally 2–4 weeks. Missing or undervalued documents can incur $100+/day demurrage fees. Choose an experienced local clearing agent. -

Any Paperwork or Transport Notes?

You need an English Certificate of Origin, commercial invoice, and packing list. Label each crate with a unique number. Inland transport costs vary—get quotes early.

Before placing your order, clarify delivery terms with your supplier. Consider all-in-one customs-inclusive delivery services to save time and avoid surprises.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)