Soybean Oil Manufacturing Process Optimization to Improve Oil Yield

Soybean Oil Manufacturing Process from Raw Materials to Finished Oil Overview

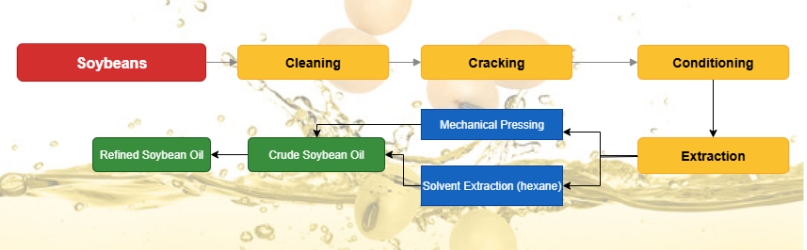

The soybean oil manufacturing process is a multi-stage industrial operation that transforms cleaned soybeans into high-quality edible oil through a series of mechanical and chemical steps. At its core, the system integrates cleaning, cracking, conditioning, flaking, pressing, and solvent extraction — each contributing directly to the overall yield and purity. In large-scale soybean oil extraction plants, production capacities can reach 300–600 tons per day, depending on line configuration and automation level.

Key Stages in the Soybean Oil Manufacturing Steps

- Cleaning and Grading: Removes impurities such as dust and stones to prevent wear on equipment. Typical impurity levels are reduced to below 0.5% after screening.

- Cracking and Dehulling: Reduces particle size to 0.25–0.35 mm, facilitating oil release.

- Conditioning and Flaking: Moisture is adjusted to 10–12%, and temperature is maintained around 70–80 °C for optimal plasticity.

- Mechanical Pressing: Initial oil yield reaches 60–65%, depending on kernel integrity.

- Solvent Extraction: Using hexane, residual oil content in the meal drops below 1%.

Comparison of Mechanical Pressing vs. Solvent Extraction

| Process Type | Typical Oil Yield (%) | Residual Oil in Meal (%) | Energy Use (kWh/t) | Recommended Application |

|---|---|---|---|---|

| Mechanical Pressing | 85–88 | 6–8 | 55–70 | Small to medium soybean oil plants |

| Solvent Extraction | 96–98 | 0.5–1 | 90–110 | Large-scale continuous production |

In modern soybean oil extraction lines, the choice between mechanical and solvent-based methods of soybean oil processing depends on production targets and sustainability goals. Combining both in a hybrid configuration can improve yield by up to 5–7% while reducing solvent usage by nearly 10%.

Simple Soybean Oil Extraction Process Flow Chart

Factors Affecting Soybean Oil Production Process Efficiency

- Moisture Content: Impacts soya oil release and extraction efficiency.

- Flake Thickness: Thinner flakes (~0.3 mm) enable faster solvent penetration.

- Extraction Temperature: Typically maintained at 55–60 °C for optimal diffusion rates.

- Solvent Ratio: Commonly controlled at 0.8–1.0 kg hexane per kg of oil.

Maximize your plant’s performance with an integrated soybean oil manufacturing process designed by our process engineers – Contact us today to start your optimization journey.

Improve Soybean Oil Yield: Efficient Pretreatment Technologies

Efficient pretreatment before cooking oil extraction plays a decisive role in achieving higher oil recovery rates. Adjusting raw material moisture, particle size, and conditioning parameters can increase oil yield by 2–4%, directly affecting profitability. In industrial-scale edible oil mill plants, every 1% yield gain can translate into savings exceeding USD 50,000 per month.

Controlling the soybean crushing fineness (typically 0.25–0.35 mm) ensures uniform heat and mass transfer during extraction. Similarly, conditioning at 70–80 °C for 15–20 minutes breaks cellular structures and improves oil release efficiency. High-precision rotary conditioners maintain consistent temperature and humidity within ±1 °C and ±0.5%, ensuring process stability.

Soybean Oil Extruding is a mechanical process that uses an soybean extruder machine to apply high temperature, short-time conditioning to whole soybeans. Inside the barrel, the material undergoes:

- Rapid heating (up to 120–150°C)

- High pressure and mechanical shear

- Instantaneous expansion at discharge

This treatment breaks oil cells and stabilizes enzymes, enabling efficient oil release when followed by mechanical pressing. The output includes crude soybean oil and extruded full-fat soy (FFS) suitable for poultry, livestock, and aquaculture diets.

Soybean Cleaning and Extruding Machines in Oil Mill Plant

Upgrade your pretreatment line with high-efficiency conditioning systems engineered to enhance soybean oil yield – Reach out for a tailored process evaluation today.

Reduce Soybean Oil Losses in Extraction Process

Optimizing the soybean oil process focuses on reducing oil loss, solvent consumption, and thermal waste. During extraction, maintaining a solvent-to-flake ratio of 1.2:1 and extraction temperature around 60 °C ensures solvent recovery rates above 98%. Adjusting extractor rotation speed by just 5–10% can reduce residual oil in meal from 1.2% to 0.8%.

Energy recovery systems reclaim up to 25–30 kWh/t from desolventizing and evaporation units. Additionally, the integration of continuous solvent monitoring sensors enhances solvent extraction efficiency while reducing environmental emissions.

Modern plants utilize two-stage filtration and advanced decanters to manage oil impurities, keeping total phospholipids below 0.03%, which simplifies downstream refining. (Related Reading: Learning Soybean Oil Filter Machine for Sale>>)

Optimize every drop – Partner with our engineering specialists to deploy oil loss reduction techniques that elevate both efficiency and profitability.

Smart Soybean Oil Processing Factory Applications and Integrated Optimization

Large Soybean Oil Mill Plant Project Image

Advanced automation and intelligent control systems now define the new standard in smart soybean oil plants. Through integrated PLC and SCADA controls, operators can achieve line-wide synchronization with real-time data visualization. This approach enhances throughput by 8–12% and reduces manual intervention hours by over 40%.

Thermal recovery and reuse of exhaust heat from desolventizing units save approximately 20–25 kWh per ton of soybeans processed. Waste meal and hulls can also be converted into biofuel pellets, cutting disposal costs by 15–20%. (You May Interested in: Cost of Starting A Soybean Oil Plant>>)

Energy recovery in vegetable oil production not only lowers operational expenses but also aligns with sustainability goals and ESG (Environmental, Social, and Governance) compliance standards. Plants with integrated heat-exchanger systems report up to 18% reduction in total energy consumption while maintaining consistent oil yield quality.

Automation upgrades using predictive maintenance analytics detect potential mechanical failures 48–72 hours in advance, minimizing unplanned downtime. Integration of MES data with ERP systems further enhances production scheduling and cost tracking across departments.

Transform your production performance with efficient soybean oil factory design and digital automation integration – Connect with our team to build your next-generation oil plant today.

The continuous pursuit of efficiency in the soybean oil manufacturing process directly supports long-term profitability and sustainability in soybean oil extraction operations. By combining advanced pretreatment, optimized process control, and plant-wide energy recovery, manufacturers can achieve higher yield, better product consistency, and reduced environmental impact.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)