Soybean Oil Refining Process Guide

Overview and Key Steps of the Soybean Oil Refining Process

Soybean oil extraction begins with the mechanical pressed or solvent-based recovery of oil from soybeans, typically yielding crude oil with impurities ranging from 0.5–2% phospholipids and 1–1.5% free fatty acids (FFA). The soybean oil refining process transforms this crude soybean oil into edible-grade oil with less than 0.05% residual impurities, suitable for food, pharmaceutical, and biofuel applications.

Degumming and Neutralizing Stages

The degumming step removes phospholipids and mucilaginous substances by adding 0.2–0.5% water or acid at 70–80°C, causing gums to separate for centrifugation. This is followed by alkali neutralization, where sodium hydroxide (NaOH) at 0.1–0.2% reacts with FFAs to form soapstock. Proper control of pH (around 7.0–7.2) ensures minimal neutral oil loss, typically under 0.2%.

Bleaching Process

Bleaching involves adsorbing pigments and trace metals using activated clay (0.8–1.2% dosage) at 95–110°C under vacuum. The process can reduce color values by 80–90%, significantly enhancing oil clarity. Bleaching earth is carefully selected to balance adsorption capacity with cost-effectiveness.

Deodorizing and Finishing

Deodorization employs steam distillation at 180–240°C under 1–3 mbar vacuum, removing odor-causing compounds and volatile residues. Final oil typically achieves peroxide values below 1 meq O₂/kg and moisture levels under 0.05%.

| Stage | Objective | Typical Parameters | Output Quality |

|---|---|---|---|

| Degumming | Remove phospholipids | 70–80°C, 0.2–0.5% acid | FFA ≤ 1% |

| Neutralizing | Eliminate free fatty acids | NaOH 0.1–0.2%, pH 7.2 | FFA ≤ 0.05% |

| Bleaching | Improve color and purity | 95–110°C, 1% clay | Color ≤ 3R (Lovibond) |

| Deodorizing | Remove odors & volatiles | 180–240°C, 3 mbar | Odorless, food-grade oil |

Soybean Oil Refining Process Control Parameters

Maintaining precise temperature, residence time, and vacuum levels is crucial. For instance, a deviation of 5°C in deodorization may increase residual FFA by 0.02%, affecting shelf life and flavor stability. Automated PLC systems help sustain consistent refining efficiency above 98% while minimizing human error.

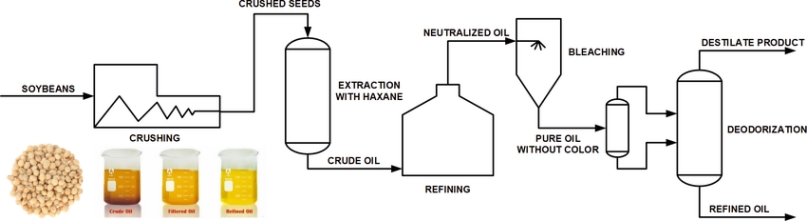

Simple Soybean to Crude Oil to Refined Oil Process Flow Chart

Unlock greater refining efficiency and oil purity — collaborate with our process specialists to develop your optimized soybean oil refining solution.

Soybean Oil Refining Equipment Configuration and Automation Control

A modern soybean oil refinery typically integrates refining towers, vacuum deodorizing units, filtration systems, and heat recovery exchangers. The refining capacity often ranges from 20 to 200 tons/day, depending on plant design. Equipment selection impacts yield by up to 2–3%, highlighting the need for precise system design.

Automated control through MES (Manufacturing Execution System) and PLC (Programmable Logic Controller) technologies ensures process consistency and real-time monitoring of temperature, pressure, and FFA content. Energy recovery from deodorizer vapors can save up to 18 kWh/ton of oil refined.

- Refining Tower: Handles neutralization and washing with improved contact efficiency.

- Vacuum Deodorizer: Maintains low oxygen environment for purity protection.

- Filtration System: Removes bleaching earth residues under 0.05% solids concentration.

Get Your Customized Refining Equipment Layout and Automation Design — Reach Out to Our Process Engineering Team Today.

Soybean Oil Refining Efficiency and Quality Enhancement by Process Optimization

To achieve high yield and consistent quality, soybean oil refining optimization focuses on balancing reagent usage and impurity removal. Adjusting bleaching clay dosage by ±0.1% can influence color stability by 15%. Similarly, solvent recovery efficiency above 95% helps cut operational costs.

Improved oil yield techniques include enhanced degumming using enzymatic aids and real-time NIR (Near-Infrared Reflectance) monitoring to detect residual phospholipids. Quality enhancement relies on better deodorizer design that reduces peroxide formation by up to 30%.

Soybean Oil Refining Plant Cost Control and Sustainable Production Strategies

The soybean oil refining cost analysis shows that utilities (steam, electricity, and cooling water) account for 25–35% of total refining costs, while chemical inputs take 10–15%. Efficient solvent and heat recovery can lower energy consumption by 12–18% per ton of oil processed. (Related Post: Learning about Soybean Oil Refinery Energy Optimization>>)

Sustainable refining emphasizes eco-friendly soybean oil production, integrating closed-loop solvent systems and low-carbon steam boilers. Waste bleaching earth regeneration and soapstock valorization into biodiesel can reduce total waste output by 40%.

Factories adopting heat integration networks (PINCH analysis) reported up to 15% annual energy savings. Coupled with soybean oil plant wastewater treatment upgrades, such strategies align with ISO 14001 sustainability standards while maintaining product competitiveness.

Advance toward greener, more cost-efficient oil refining — connect with our sustainability engineers for a tailored production roadmap.

By implementing these advanced process controls and optimization methods, manufacturers can ensure higher yield, purity, and sustainability across the entire soybean oil refining process, forming a strong foundation for efficient and scalable soybean oil extraction operations.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)