In many emerging countries and regions, the consumption of edible oil is growing rapidly, but local edible oil production capacity is lagging far behind. Heavy reliance on imports and price volatility have become prominent market issues. For those with raw material resources or intentions to invest in agricultural processing, building a local edible oil production plant is a practical and stable return-oriented direction.

This is not a trend driven by hype, but a long-term business centered around essential consumer goods. There is a real market gap behind it, along with growing policy support.

In this column, we will focus on the edible oil production business in emerging markets—from development potential and factory setup opportunities to equipment selection. You can browse the related articles below to gather more information or contact the ABC Machinery expert team for targeted advice.

- [South Africa] Guide to Sunflower Oil Machine Prices and Buy Wisely

- [India] Cooking Oil Plant Market: Business Opportunities and Setup Guide

- [South Africa] How to Choose Energy-saving Oil Press Machines

- [Nigeria] How Much Does a Groundnut Oil Processing Plant Really Cost?

- [Nigeria] How to Start a Profitable Palm Oil Production Business?

- [Nigeria] Comprehensive Guide to Setting Up a Soybean Oil Production Plant

- [Philippines] Choose Perfect Coconut Oil Making Machine for Your Business

ABC Machinery’s Successful Oil Mill Plant project Reports

These experiences help us better understand the policy, environmental, and technical differences in various markets. We can provide localized advice and customized configurations based on the actual needs of customers in different countries.

Global Edible Oil Production Overview – 2025/26 Market Data Reveals Industry Trends

If you’re considering investing in edible oil production equipment or establishing an oil processing business, understanding the latest global oil production trends is crucial. According to the 2025/26 forecast, the oil industry is in a growth phase—ample raw materials, rising processing demand, and active end-user markets are creating real opportunities for equipment purchases and edible oil production projects.

- Global increase in oil crop output ensures raw material supply

In 2025/26, global oil crop output is expected to reach 692 million tons—a historical high. Soybean production is projected to exceed 420 million tons, while rapeseed and sunflower seed outputs will also grow. This means companies planning to build or expand oil mills will have a stable raw material supply, supporting long-term edible oil production operations.

- Rising oil extraction demand increases equipment utilization rates

Global oilseed pressing is expected to reach 580.5 million tons, a growth of over 3% year-on-year. Soybeans will account for nearly 70% of this, not only for food oil, but also for feed and industrial applications such as biofuels. As demand diversifies, edible oil production lines rely increasingly on efficient and automated oil processing machinery.

- Active end markets boost both exports and domestic sales

Consumption of soybean oil, sunflower oil, and rapeseed oil is expected to continue rising across emerging markets such as China, India, Southeast Asia, and Africa. In populous nations like India and China, demand is growing in both food and industrial sectors. For instance, China’s soybean imports in 2025/26 are projected at 112 million tons—making it a key driver of edible oil production in world.

Investment Tip: Now is the time to upgrade your edible oil making machines

For enterprises planning to invest in oil processing plants or machinery, this is the ideal time window. Prioritize highly automated, energy-efficient oil extarction machines to improve unit output and reduce operating costs. Tailoring edible oil production line size and configuration to market demands also helps control upfront investment.

Reliable Cooking Oil Production Machine Manufacturer - ABC Machinery

Why the Edible Oil Business in Emerging Markets is Worth Investing In

In emerging markets such as Africa, Southeast Asia, and South Asia, consumption of edible oils is rising rapidly. However, local edible oil production capacity is far from keeping up. This mismatch of “strong demand + weak processing” presents a clear investment opportunity. (Related Reading: Buy Cost-effective Sunflower Oil Extraction Machines in South Africa>>)

| Africa | Southeast Asia | South/Central Asia | |

|---|---|---|---|

| Oil Crop Resources & Status | Rich in palm, sesame, groundnut, sunflower seeds—mainly in Nigeria, South Africa, Tanzania, Ghana | Indonesia & Malaysia have mature palm oil systems; Myanmar, Cambodia, Laos have untapped resources | India is a major consumer; Central Asia improving crop cultivation |

| Processing Capacity Overview | About 3.4 million tons of crude palm oil annually; weak refining capacity | Indonesia: 44 million tons/year; Malaysia: 19.7 million tons/year; others rely on imports | India heavily relies on imports (16.5 million tons); Central Asia attracting food processing investment |

| Market Demand & Policy Orientation | Local farming and processing encouraged (e.g. Ethiopia, Egypt aiming for self-sufficiency) | Small countries have fast-growing cultivation and low labor costs | India pushes "National Edible Oil Mission"; Uzbekistan and others promote oil mill projects |

| Investment Opportunity Advice | Start small-to-medium local oil pressing/refining plants business to meet rising demand | Build primary processing units in resource-rich countries or refined oil factories in small nations | Supply crude/semi-refined oil to India; enjoy tax incentives by building factories in Central Asia |

ABC Machinery: Start Your Edible Oil Project With Confidence

If you’re planning to invest in edible oil production, we offer one-stop factory setup services from scratch. More than selling equipment, we help you design the right oil production solution and technical process based on your materials, budget, and target market.

We also have a multilingual sales and engineering team fluent in English, French, Spanish, and Russian, with local partners and engineers stationed in select countries for timely support and communication.

ABC Machinery and Our Oil Mill Projects Customers

Edible oil projects in emerging markets offer low entry barriers and fast launch potential. Whether you’re starting a home workshop, cooperative, or regional plant, proper planning and the right machines are the keys to success. Contact us for a customized solution today!

Basic Structure of an Edible Oil Production Line

A standard edible oil production line project can start from a small oil mil plant of 5 tons per day, or expand to integrated oil production lines producing 100+ tons per day. The key lies in designing the right process and equipment configuration based on investment scale, raw material supply, and market direction.

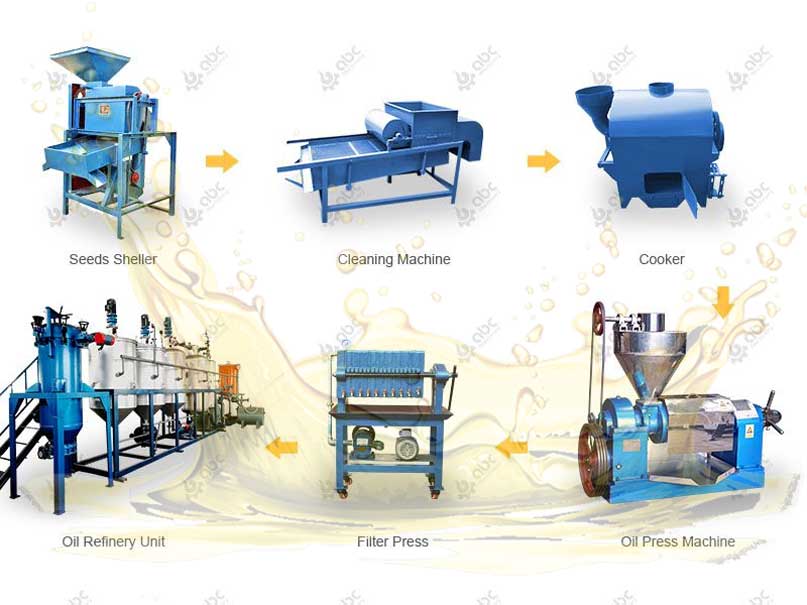

A Small Vegetable Oil Extraction Line Equipment Setup

How to set up a complete edible oil processing plant? Whether for small-scale or industrial-level production, the basic structure remains similar and includes the following core workshops: (You may be interested: Vegetable Oil Processing Plant Setup Cost>>)

1. Oilseed Pre-Treatment Section

Purpose: To clean impurities (stones, dust, mold, etc.) from oilseeds and soften them, preparing for pressing or solvent extraction.Common equipment: cleaning sieve, destoner, dehuller, crusher, conditioning tank (to improve oil yield)

Tip: Pre-treatment has a big impact on yield and oil quality—don’t overlook it.

2. Pressing / Solvent Extraction Section

Based on material and output goals, two main processing methods are used:

Mechanical Pressing: Simple process, easy to operate, suitable for high-oil crops like sesame, peanuts, sunflower seeds. Key machinery: screw oil press machine.

Chemical Solvent Extraction: High oil yield, ideal for large capacity operations using low-oil crops like soybeans or cottonseed. Key machinery: extractor, desolventizer toaster, solvent recovery system.

Some plants use a combined method (pressing + solvent extraction) for better quality and output.

3. Refining Section (optional depending on product goals)

Function: Refine crude oil by removing gums, waxes, pigments, mechanical impurities, etc., to meet market standards.

Typical process: degumming → neutralizing → bleaching → deodorizing → filtering & cooling

Recommended for: supermarket oils, branded packaging oils, export-grade products

Key Equipment: edible oil refinery line

4. Auxiliary Systems

These systems ensure operational efficiency and stability. Common units include: steam boiler, electric control systems (automation), oil storage tanks, and packaging lines, oil press machine spare parts.

Other requirements include epoxy-coated floors (for environmental compliance), hygienic workshop environments (food-grade standards), and product labeling. Once all are in place, a fully standardized edible oil factory is ready.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)