Start A Profitable Peanut Oil Business Effectively

This column focuses on practical information for peanut oil production, offering a systematic breakdown of processes from peanut pre-treatment, pressing, solvent extraction, refining, to cold-press specialty techniques and related processing machines. Whether you are planning to build a new peanut oil mill plant, sourcing peanut oil processing equipment, or upgrading your production line, you can find clear and actionable answers here.

Seven Core Articles in This Column: Covering the Entire Production Chain

To help you quickly gain a systematic understanding of peanut oil production, this column features seven articles that follow the logical sequence of factory production processes:

- Cold Pressed Peanut Oil Why Different? Full Process and Machines Guide

- How to Choose Peanut Oil Solvent Extraction Plant? Types and Application Recommendations

- Full Peanut Oil Refining Process Explained

- Screw Oil Press vs. Hydraulic Oil Press: Which Peanut Oil Machine Suits Your Factory?

- Comparison and Selection Guide for Peanut Oil Extraction Process

- Understand the Peanut Preprocessing Workflow for Oil Production in One Read

- Comprehensive Guide to Peanut Oil Solvent Extraction Process

Seizing the Mid-Term Growth Window in Peanut Oil Production

Third-party research consistently indicates stable growth: the global peanut/groundnut oil market size in 2023–2024 is estimated at approximately USD 1–1.2 billion. Although different institutions report slightly varying figures, the projected CAGR over the next decade is roughly 3.4%–4.6%. The Asia-Pacific region (especially China and Southeast Asia) remains the primary demand driver. This suggests that, with clear raw material sourcing and brand positioning, medium-scale new peanut oil processing plants or technology upgrade projects can generate significant cash flow and offer attractive exit potential.

Key Knowledge Points in Peanut Oil Processing: Details That Determine Investment Success

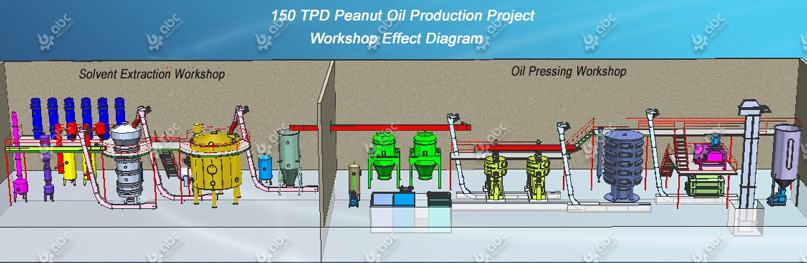

Industrial 150TPD Peanut Oil Mill Plant Project Design

In peanut oil production, process selection are the core factors that determine investment returns:

- Pre-treatment stage: After crushing, peanuts are kept in 4–6 kernels per piece, with moisture controlled at 7%–9%, which significantly improves pressing efficiency. Although pre-treatment accounts for only about 15% of total investment, it can determine whether the oil yield reaches the design target.

- Combination of pressing and solvent extraction: Pure mechanical pressing achieves an oil yield of about 41–46%, while the “pre-pressing + solvent extraction” process can increase yield to 48–55%. This difference directly affects cash flow and payback period.

- Refining process: Degumming, neutralization, bleaching, deodorization, and winterization not only enhance groundnut oil purity but also determine eligibility for high-end retail or export markets.

These seemingly minor stages are often the “profit switches” most overlooked by investors and buyers, and are key points that this column will continue to explore in depth.

Even within peanut oil production, different processes show significant differences in oil yield and investment returns. Public research and industry data indicate that under optimized roasting conditions, mechanical pressing typically achieves an oil yield of about 41–46%, while solvent extraction can reach a higher range of 48–55%. Cold-press routes usually yield below 40%, suitable for premium niche products. These figures directly impact your calculations and pricing strategy for raw material utilization, solvent balance, and finished product consumption.

Connect with Professional Teams for Solutions: EPC Turnkey Support for Oil Pressing and Refining

If you are planning a peanut oil production line, we can provide:

- Process route and capacity configuration plans;

- Equipment list (BOM), energy consumption, and investment calculations;

- EPC turnkey delivery of the complete plant (including installation, commissioning, and training);

- Compliance and quality standards support.

Commercial Peanut Oil Production Factory - Prepressing and Solvent Extraction Workshop

Our engineering team has extensive experience with domestic and international projects, familiar with the full-chain process and machines of edible oil pressing—solvent extraction—refining—bottling. Simply provide your annual raw material volume, target production capacity, and budget range to receive a free preliminary consultation and a one-page plant setup draft. Contact us today to turn your ideas into actionable solutions.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)