Cost-effective Penut Oil Making Machine Purchase Guide

When investing in a factory setup or purchasing peanut oil machine equipment, choosing the right press is crucial for ensuring both oil quality and production efficiency. Screw oil press machines and hydraulic oil presses each have unique advantages and limitations, directly affecting oil yield, residual oil content, and the flavor profile of peanut oil. This article provides a comprehensive analysis from technical principles, factory scale compatibility, raw material adaptability, and application case perspectives, helping you select the most suitable peanut oil extraction machine for your processing needs.

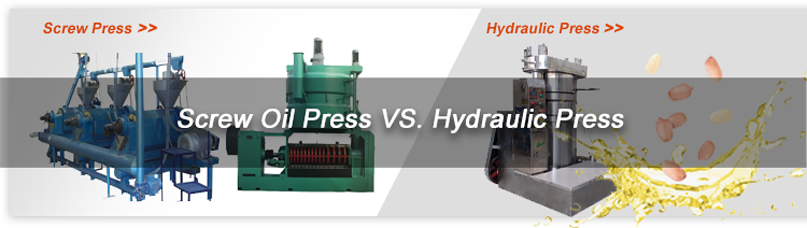

Core Differences Between Screw Oil Press and Hydraulic Oil Presses in Peanut Oil Production

In peanut oil production, the choice between a screw oil press machine and a hydraulic oil press machine impacts not only equipment cost but also production efficiency, oil quality, and downstream processing complexity. Understanding their core differences is the first step in selecting the right machine for your oil mill plant.

Impact of Working Principles and Pressing Methods on Peanut Oil Quality

Screw oil press machines operate on the principle of continuous screw advancement, where peanuts are gradually pressed under high pressure and friction. They are characterized by high capacity and automated continuous operation, making them widely used in medium to large-scale peanut oil factories. Due to frictional heat, even under “cold-pressing” conditions, oil temperatures often reach 40–60℃. This method effectively releases oil, but insufficient temperature control may affect some active nutrients (such as tocopherols) and aromatic compounds. Residual oil content typically ranges around 6–8%, which can be further reduced through multi-stage pressing or combined extraction processes.

Hydraulic oil presses, on the other hand, use static high pressure to directly squeeze oil from raw materials. The pressing process is gentler, with controllable temperatures, closer to “physical cold pressing.” Without pre-roasting, hydraulic pressing typically produces light yellow peanut oil with a delicate raw nut aroma, suitable for high-end, original-flavor products. Its limitation is batch production, with lower single-machine capacity. To achieve higher oil yield, peanuts often require mild roasting or steam conditioning before pressing, allowing cell walls to break more easily and reducing residual oil content to 4–6%.

In practice:

- Screw oil press machines: Suitable for medium to large-scale factories seeking stable output and higher overall oil yield; also compatible with downstream extraction or refining processes.

- Hydraulic presses: Ideal for premium oils, small-batch production, or cold-press flavor emphasis, giving an edge in markets focused on “original aroma” and nutrient preservation.

| Indicator | Screw Oil Press Machine | Hydraulic Press |

|---|---|---|

| Production Mode | Continuous | Batch |

| Oil Yield | 38–42% | 36–40% |

| Residual Oil | 6–8% (single pass)/1–2% (with extraction) | 7–9% (cold press)/4–6% (mild roasting) |

| Oil Flavor | Golden, roasted aroma | Light, raw nut or lightly roasted aroma |

| Target Market | Mass edible oil, catering wholesale | Premium cold-pressed oil, high-end retail |

| Single-Machine Capacity | High, suitable for large-scale | Lower, suitable for small batches |

Cooking Oil Extraction Machines Manufacturer - ABC Machinery

With clear raw material and target market specifications, ABC Machinery can assist in selecting the right peanut oil machine and designing the production line configuration.

Factory Scale and Peanut Oil Machine Matching Strategy

When deciding which peanut oil machine to purchase, the factory’s production scale and market positioning are critical factors. Different capacity ranges require completely different equipment. A wrong choice not only affects return on investment but may also hinder market success.

Small/Home Use Peanut Oil Production Machine Line

Small oil mills (daily processing of 0.5–5 tons of peanuts) often face two challenges: limited investment and fast market entry. Which is better: hydraulic press or screw oil press machine?

- If aiming for a premium route (small packaging, high price), a hydraulic oil press machine is preferable. Its low pressing temperature better preserves the peanut’s natural aroma and nutrients, making the oil easier to sell at a premium.

- If aiming for volume (catering channels, mass oil), a screw oil press machine is the first choice. Continuous operation and high oil yield ensure rapid ROI, especially suitable for wholesale or catering supply markets.

- If serving both market types, consider a “small screw oil press + hydraulic press” combination: ensuring stable output while producing high-end cold-pressed oil when needed.

Medium to Large/Industrial Peanut Oil Production Lines

When daily output reaches 20 tons or more, production strategy changes. At this stage, equipment configuration must focus on efficiency, stability, and cost control:

Complete screw oil press machine production lines form the backbone of medium to large cooking oil processing factories. Continuous, highly automated operation suits large-scale supply for catering, wholesale, and industrial edible oil markets. The role of hydraulic presses in industrial production is supplementary. They are typically used for small-batch high-end cold-pressed oils, helping factories expand into high-margin niche markets.

How to Quickly Identify Your Matching Solution?

- If your planned investment is under $70,000 USD and the target market leans toward local catering or retail, prioritize screw oil press machines and supplement with a hydraulic press if necessary.

- If your budget is over $140,000 USD and the goal is large-scale supply or export, consider a complete screw oil press machine production line and retain hydraulic cold-press options to diversify product offerings.

If you are planning a peanut oil processing factory, we recommend contacting our engineering consultant team to receive a complete oil extraction machines configuration plan tailored to your capacity and budget.

Click “Consult Now” below to determine the most suitable peanut oil machine solution and avoid losses from improper equipment selection.

Application Cases of Screw Oil Press Machines and Hydraulic Presses in Edible Oil Processing

In practical peanut oil production, both screw oil press machines and hydraulic presses have advantages. Different types of factories choose equipment based on output, market positioning, and raw material characteristics.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)