In a peanut oil production line, preprocessing is the critical first step that determines success. At first glance, this stage may seem like merely “preparing” raw materials, but in reality, it directly affects oil yield, oil quality, and the energy consumption and cost of subsequent refining processes. For example, incomplete cleaning can allow metal debris into the press, causing premature bearing wear; insufficient conditioning may prevent oil cells from fully rupturing, reducing oil yield by 2–3%, which translates into significant losses in ton-scale production.

Improtance of Peanuts Preprocessing in Oil Production Process

For businesses planning to set up a peanut oil production plant or procure equipment, understanding the preprocessing workflow is not just about knowing the “sequence of steps.” It is a key factor in evaluating future plant efficiency, energy consumption, and maintenance costs. This article provides a comprehensive view of the key steps in peanut preprocessing and essential factory construction considerations, helping you make informed decisions.

Panorama of Peanut Preprocessing: From Raw Material to Oil Extarction-Ready State

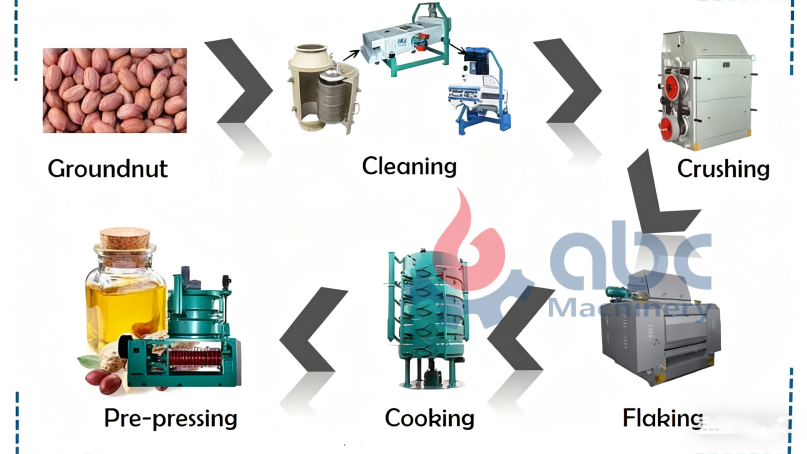

In a standardized peanut oil production line, the preprocessing workflow mainly consists of three key stages: cleaning & dehulling → crushing & flaking → conditioning & roasting. Each step prepares the peanuts for the final oil extraction process.

Cleaning & Dehulling: Ensuring Oil Purity and Equipment Safety

Incoming peanuts often contain stones, soil, metal pieces, or other crop seeds. If these impurities enter the next process, they can easily jam the press, cause wear, or even stop the entire line. The cleaning stage typically employs vibrating screens, magnetic separators, and destoners to keep impurity levels below 1%.

Next is dehulling. Peanut shells affect oil release during pressing and increase wear and energy consumption. Typically, a dehulling rate of over 95% is required for stable production.

Crushing & Flaking: Breaking Cell Walls to Release Potential Oil

Peanut oil is stored within cell walls. Only through crushing and flaking are the cell structures broken, making oil easier to extract during pressing.

- Crushing: Usually done with a toothed roller crusher, reducing peanuts to 4–6 pieces in size. Too fine increases powder, affecting subsequent roasting and pressing; too coarse leaves cells unbroken, reducing oil yield.

- Flaking: Crushed peanuts are pressed into thin slices (thickness ~ 0.3–0.5 mm), increasing surface area and allowing water and heat to penetrate evenly.

Conditioning & Roasting: Optimizing Moisture and Temperature

After flaking, peanut slices undergo conditioning and roasting. The goal is to adjust moisture and temperature so that the peanuts release oil efficiently during pressing without clumping.

- Conditioning: Water or heat is applied to maintain moisture at 7–9%. Too high moisture makes cake loose; too low increases press wear.

- Roasting: Heated in a cooker to around 105–110℃, denaturing proteins and enhancing oil fluidity.

Experienced operators often say, “Roasting is the final critical step.” A 5℃ difference in roasting can change oil yield by 1–2% for the same batch of peanuts.

For small-scale cold or simple hot groundnut oil production lines, many home-style operations skip flaking, performing only crushing + roasting before feeding small screw oil presses. (Read More: Small Groundnut Oil Mill Business Plan>>)

Buy Small Peanut Oil Mill Plant With a Cooker (Groundnut Kernels)

Key Considerations for Building a Peanut Oil Preprocessing Workshop

In peanut oil production, the preprocessing workshop not only performs initial raw material processing but also directly impacts pressing efficiency, equipment lifespan, and safety management.

Workshop Layout and Material Flow Design Principles

The groundnut oil pretreament layout should follow “raw material entry → cleaning → dehulling → crushing/flaking → conditioning/roasting → product transfer” to create a smooth, unidirectional flow. Core design principles include:

- Smooth material flow: Avoid cross-contamination between raw materials, intermediates, and waste to reduce risk; Linear or U-shaped layouts are recommended; small peanut oil press plants may adjust to L-shaped for flexibility.

- Equipment spacing and operational space: Provide wide aisles for manual intervention, maintenance, and handling; Leave adequate protective and cooling space between crushers, flakers, and roasting units.

- Zoning management: Clearly define cleaning, dehulling, crushing/flaking, and conditioning/roasting zones;Plan storage for raw materials, intermediates, and waste separately to minimize cross-contamination.

- Logistics and auxiliary facilities: Use simple hoppers, conveyors, or small lifts to reduce manual handling; Small peanut oil production line can combine manual and mechanical handling for cost-effectiveness and efficiency.

Tip: During early planning, visualize the material flow and estimate space for aisles, storage, and equipment according to production capacity to avoid costly modifications later.

Key Preprocessing Equipment in Cooking Oil Pretreament Stage

Production Machines used in Peanut Oil Pre-pressing Process

- Cleaning Equipment: Vibrating screen, Magnetic separator, Destoner (optional).

- Dehulling Equipment: Semi-automatic dehullers suit small plants with dehulling rates of 90–92%. Choose models that are easy to clean and wear-resistant to avoid over-investing in full automation.

- Crushing & Flaking Equipment: Toothed roller crusher, Flaker.

- Conditioning & Roasting Equipment: Single-kettle roaster is sufficient for small plants, with temperature control and even steam distribution.

- Conveying & Auxiliary Equipment: Small hoppers, lifts, or simple conveyors reduce manual handling and ensure smooth material flow; standardize interfaces for future expansion or equipment replacement.

Investment Suggestions:

- For small plants, choosing reliable, easy-to-maintain, cost-effective equipment is more important than full automation;

- Flexibly combine equipment according to raw material quality and production capacity to avoid high upfront costs;

- Focus on wear resistance and temperature stability of crushing, flaking, and roasting equipment, as these directly determine oil yield and quality.

Considerations for Steam, Electricity, and Storage System

The steam system is critical. Conditioning and roasting require stable steam supply. Small plants can use a single-kettle steam line with adjustable pressure and temperature to maintain 105–110℃. For peak demand or short stops, reserve buffer tanks or steam storage.

Electricity is equally important. Crushers, flakers, and conveyors need stable power. Small plants can use single-phase or three-phase distribution, with overload protection and separate circuits, and reserve interfaces for key equipment to ensure continuous production.

Storage and warehouse layout should ensure raw materials are dry and ventilated. Intermediate products and peanut slices should be close to roasting or pressing units to minimize handling. Finished oil or cake should have ventilated or cooling areas to maintain pressing efficiency. Sufficient space for maintenance is also important for cleaning and inspection.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)