Learning Solvent Extraction of Groundnut Oil

In peanut oil production, although mechanical pressing is widely used, the pressed peanut cake still contains a significant proportion of residual oil, which directly affects a factory's output efficiency and profit margin. For businesses planning to invest in building a plant or purchasing equipment, understanding the edible oil solvent extraction process can not only improve oil recovery but also optimize production costs and by-product utilization. This article provides a comprehensive analysis of peanut oil solvent extraction technology, covering process principles, workflow, and cost-effectiveness to help you make informed decisions.

Why Can Peanut Cake Still Yield Oil? — Understanding the Principle of the Solvent Extraction Process

Residual Oil in Peanut Cake and the Limitations of Mechanical Pressing

During mechanical pressing, peanuts are squeezed using a screw oil press machine or a hydraulic oil press machine. Even with mature technology, the peanut cake after high-pressure pressing still contains approximately 8%–12% residual oil. This portion of oil is difficult to extract purely through mechanical pressure due to the following reasons:

- Structural Limitation: Oil in peanut seeds is largely enclosed within cell membranes, and mechanical pressing cannot fully break the cell structure, leaving some oil trapped in fibers.

- Process Temperature Control: Pressing temperature and pressure must balance oil quality. Excessive heat can damage flavor and nutrients, while low temperature prevents sufficient oil release.

- Equipment Capability Limits: Screw oil press machines and hydraulic presses have physical limits in oil yield. Adjusting rotation speed, screw length, or heating cannot entirely eliminate residual oil.

Basic Principle and Overview of the Solvent Extraction Process

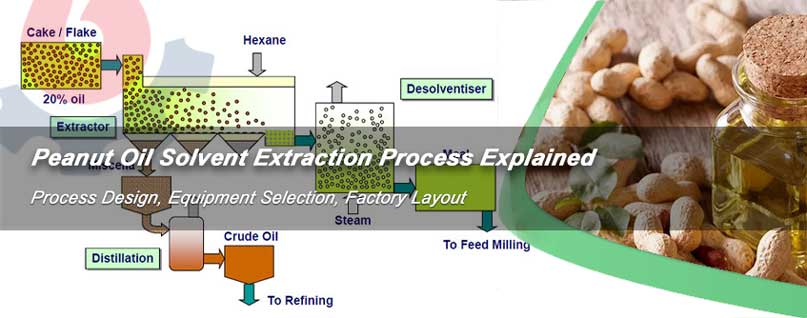

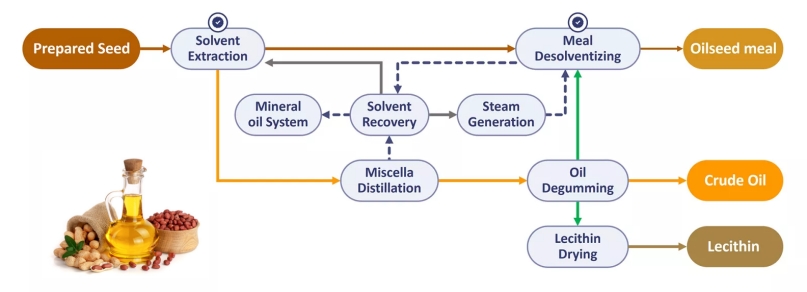

The solvent extraction process is the mainstream technology for extracting groundnut oil in large industrial oil mill plant. Its core principle is using an organic solvent (such as n-hexane) to selectively dissolve oil, achieving high-efficiency extraction. The basic workflow includes:

Step by Step Peanut Oil Solvent Extraction Process Flow

- Extraction: The crushed and conditioned peanut cake is contacted with solvent, dissolving oil into a mixed solution.

- Separation: Residue (defatted cake) is separated from the oil-solvent mixture by filtration or centrifugation.

- Distillation and Solvent Removal: The mixture is heated to evaporate and recover the solvent, leaving high-purity peanut oil.

- Solvent Recovery: The evaporated solvent is condensed and recycled, achieving energy savings and environmental protection.

Read More: Different Types of Solvent Extraction Machines for Vegetable Oil Production>>

Key Advantages:

- High Recovery Rate: Over 90% of residual oil in peanut cake can be extracted, raising overall oil yield to 45%–50% (depending on raw material and preconditioning).

- By-Product Utilization: Defatted cake is rich in protein and suitable for animal feed or as raw material for food additives, adding extra value.

When planning a peanut oil production plant, combining mechanical pressing with the solvent extraction process can significantly improve oil yield and economic efficiency. Understanding the workflow and critical steps is essential for equipment selection and plant layout.

Submit your inquiry to receive a free peanut oil solvent extraction process design plan!

Synergistic Advantages of Combining Solvent Extraction with Mechanical Pressing

In practice, the dual process of mechanical pressing + solvent extraction has become the industry standard for maximizing peanut oil yield. The core concept is: first, recover most oil through a screw or hydraulic press, then use the solvent extraction process to treat residual oil for maximum utilization.

- Layered Extraction: Mechanical pressing is suitable for rapid, high-temperature extraction of main oil content while maintaining oil quality; the solvent extraction process targets residual oil, overcoming mechanical limits.

- Flexible Capacity Management: Factories can adjust the production ratio between mechanical and extraction stages according to raw material volume, market demand, and oil price fluctuations to optimize economic benefits.

- Diversified By-Products: Pressed peanut cake retains protein and fiber. After defatting through the solvent extraction process, it can be used as high-value feed or protein powder, generating secondary revenue.

Profitable Peanut Oil Solvent Extraction Plant Setup

Typical Case: A medium-sized plant processing 2,000 tons of peanuts achieved 36% oil yield via mechanical pressing and recovered an additional 9% residual oil using the solvent extraction process. The combined oil yield reached 45%. This means raw materials that previously generated only CNY 720,000 in oil revenue can now reach CNY 900,000, an increase of approximately CNY 180,000/year, significantly shortening the investment payback period.

Consideration Tip: For investors planning to build a plant, the dual-process model not only improves oil yield but also increases profit flexibility and product diversity, serving as a key criterion for evaluating equipment investment portfolios.

Book a consultation with our engineers for a one-on-one peanut oil production business plan session!

Other Considerations in the Oil Solvent Extraction Plant Production

The Role of Peanuts Pre-Processing

The pre-processing stage of the solvent extraction process directly affects oil recovery efficiency and solvent utilization. The main steps include crushing, conditioning, and heating:

- Crushing: Peanut cake must be crushed to an appropriate particle size (usually 2–4 mm) to increase surface area and facilitate oil dissolution. Particles that are too coarse reduce solvent contact efficiency, while overly fine particles may affect equipment permeability and extraction speed.

- Conditioning: Adjust moisture content to 6%–8% to soften protein fiber structure, making oil more easily soluble in the solvent while preventing excessive moisture from diluting the solvent.

- Heating: Heat the peanut cake to 60–80℃ to reduce oil viscosity, increase dissolution speed, inhibit microbial growth, and prevent oil rancidity.

By-Product Handling and Environmental Safety Management

The solvent extraction process not only focuses on oil recovery but also emphasizes by-product utilization and environmental safety. After extraction, the defatted cake—rich in protein—can be used as animal feed or a food raw material, provided that moisture, solvent residue, and dust are properly controlled. At the same time, solvent management is critical, as organic solvents such as n-hexane are volatile and flammable; therefore, closed transport, condensation recovery, and explosion-proof systems are required to ensure safety. In addition, the process may generate solvent vapor emissions and oily wastewater, which must be treated through absorption, condensation, or biochemical systems to guarantee compliant and environmentally responsible discharge.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)