Generally, the oil obtained from oil extraction factory / oil mill is crude oil, which contains impurities, which are naturally present or are produced during production or storage and cannot be sold to the market. If you want to sell the oil on the market, you have to remove the impurities from the crude oil. The purpose of edible oil refinery plant is to remove solid impurities, free fatty acids, phospholipids, gums, waxes, colors, odors, etc. from the crude oil. (click to see low-cost mini oil refinery plant in india >>)

Offer Customized Oil Milling and Refining Business Plan

ABC Machinery is a professional manufacturer/supplier of cooking oil refinery machines with long established history. If you have an idea for investing an edible oil refining factory, we can offer you a customized business plan according to your needs.

Types and Selections of Complete Edible Oil Refinery Plant

Edible oil refining is a complex but flexible project that requires to select suitable edible oil refinery plant, which depends on your purpose of oil refinery, technical conditions, and economic efficiency. There are three different types of edible oil refining machine according to the degree of automation on the market: batch oil refinery plant, semi-continuous oil refinery plant, and fully continuous oil refinery plant.

Main Types of Vegetable Oil Refining Equipment

ABC Machinery engineers suggest that you can choose different types of oil refining equipment depending on the daily processing capacity of your factory, the degree of refined oil, and your investment budget. (You may be interested in cooking oil making machine >>)

| Types | Capacity suggested |

|---|---|

| Batch oil refinery plant | 1-20TPD |

| Semi-continuous oil refinery plant | 10-50TPD |

| Fully continuous oil refinery plant | >30TPD |

Three different types of edible oil refining equipment have their own characteristics and advantages, so choose the suitable oil refining equipment according to your situation and needs. ABC Machinery, a manufacturer of edible oil production plant, can customize the edible oil refining process and cooking oil refinery plant line for you. If you have any demand, welcome to call and contact us!

Edible Oil Refining Process steps

Before you decide to buy cooking oil refining machine, you need to know about oil refining process. Refining crude oil into edible oil requires deep process knowledge.

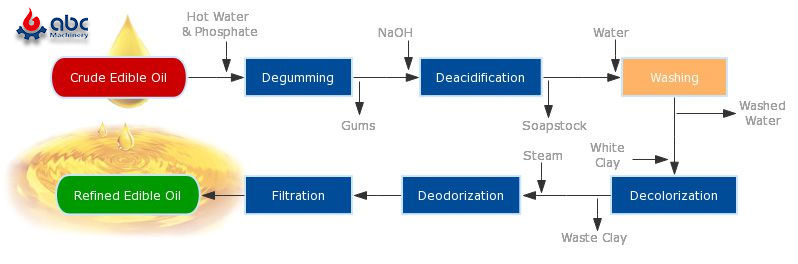

Processing Flow Chart of Vegetable Oil Refinery Factory

- Hydration degumming: According to the hydrophilic nature of colloidal impurities, adding a certain amount of hot water to the hot crude oil while it is being stirred to make the colloidal impurities in it absorb water and coalesce and sink for separation.

- Alkali refining deacidification: Using alkali to neutralize the free fatty acid in the crude oil, generating fatty acid sodium salt, and adsorb a part of other impurities, sink and thus separation from oil.

- Adsorption decolorization: Using certain substances with strong adsorption of pigments, adsorbing pigments in crude oil under certain conditions as well as some other impurities.

- Water vapor distillation deodorization: Based on the volatility of odor substances and oil is very different, in high temperature and high vacuum conditions, passing water vapor into the crude oil containing odor substances, as odor substances have a low boiling point, they are removed by water vapor.

- Cooling crystallization separation dewaxing: According to the melting point difference between wax and grease and the physical property that the solubility of wax in grease becomes smaller as the temperature decreases, the crystal wax is precipitated by cooling, and then the two are separated by filtration or centrifugation.

Excellent Manufacturers & Suppliers of Edible Oil Refinery Machines

Oil refining equipment is mainly used to remove harmful substances and impurities from the crude oil to improve the storage time and quality of edible oil and meet the national standard-grade edible oil quality requirements.

In addition, the economic value of the refined oil will also be improved, so which cooking oil refinery machine manufacturer/supplier is the best to selected? This requires a comprehensive consideration of the manufacturer's Production Capability, the quality of the equipment, and whether the manufacturer's after-sales service is perfect.

Manufacturer's Production Capacity

A qualified edible oil refinery plant manufacturer is mainly reflected in the production scale, equipment manufacturing technology, and other aspects. If a manufacturer's production scale is larger and its technology is more mature, it can ensure the quality of the oil refining equipment to achieve customer processing needs and meet the customized design. Oil refining machine manufacturing technology is directly related to the stability of the edible oil refining process and whether the indicators of refined oil are up to standard.

The quality of oil refinery machine

Edible oil mill project is a long-running project, and not a short-lived processing. Therefore, when choosing a cooking oil refining plant manufacturer, you should see how the quality of the equipment and remember not to measure the quality of the machines only by their price. You should consider a combination of quality and price, and compare three to ensure that the suitable edible oil refinery plant supplier is chosen.

Manufacturer's After-Sales Service Level

For long-lasting oil refining projects, the follow-up maintenance and repair of equipment is very important, which is to say that the after-sales service of an oil refining equipment manufacturer. A qualified oil refinery equipment manufacturers will ensure the quality of their equipment and regularly visit customers to understand their operation conditions and perform the corresponding repairs and maintenance.

As mentioned above, ABC Machinery can be said to be a reliable manufacturer. We have had many successful cooking oil refining projects in several countries, such as Afghanistan, Philippines, Jamaica, etc.

Project Report on Vegetable Oil Refinery Manufacturing Plant

We have our own factory with professional edible oil refinery equipment manufacturing capability, which can provide you with any output and guarantee the quality of the equipment. At the same time, we also have a specific after-sales service department, which can send staff to install, check and debug for you to ensure the normal operation of the equipment. (Read more: cooking oil production machine in Zambia)

Vegetable Oil Refinery Machine Price

After understanding how to choose the manufacturer of edible oil refinery plant, the cost of oil refining factory is more concerned. In fact, the price of oil refining machine is determined by the degree of refining, the daily processing capacity, edible oil refining plant layout and the equipment materials required by the customer.

The amount of output determines the oil refining equipment specifications and configuration, the greater the output, the higher the price. In addition, the degree of oil refining determines the edible oil refining factory contains which process steps. General cooking oil refining process steps include degumming, deacidification, decolorization, deodorization, etc., but if producing ordinary edible oil, degumming, deacidification, and filtration will be sufficient. However, for the production of national-level edible oil, decolorization and deodorization are also required, and the cost of the edible oil refinery plant will be higher. Besides, the material and quality of the equipment are also the factors that affect the price of oil refining machine.

If you are ready to start an edible oil refinery business, we can design the oil refining process and provide you with a suitable quotation according to your production needs.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)