ABC Machinery is now one of the largest Oil Processing Machine manufacturers and suppliers in China, with its headquarter in Anyang, Henan. Since 1990s. We has engaged in designing and manufacturing the most cost-effective Commercial Oil Press Machine for various vegetable plant seeds, including sesame seeds, palm kernel, groundnut/peanut, sunflower seeds, mustard seeds, soybean, cottonseeds, rape seeds and more.

With years of development and improvement, our sesame oil processing technology and machinery has been well recognized by our customers all over the world. We can supply completely custom business plan for sesame oil processing from small scale to large scale, from oil extraction, oil refining to oil filling. In addition, we will help customers to low the investment cost under the premise to produce high quality sesame oil based on the requiements.

How to Set up Sesame Oil Processing Plant?

Sesame oil manufacturing process is relatively complicated, but, backed with the advanced oil extraction machine, it will become easier to set up an efficient oil manufacturing plant factory for sesame oil. To ensure high quality sesame oil and long-term profits, the oil manufacturing factory should include the whole process for sesame oil production, including sesame seed treatment, such as cleaning, cooking, sesame oil pressing and sesame oil refining.

Small Sesame Oil Production Line

Sesame Oil Manufacturing Plant - Project Report

20TPD Sesame Oil Processing Plant Setup in Thailand

Recently, we have just successfully set up a complete sesame oil processing plant in Thailand. The whole factory plant is rebuilt and expanded on a old plant. Our engineers strictly designed the factory layout on the combination of customers' request and sesame oil manufacturing process to ensure long-term operation and maximize economic profits. If you are interested in setting up a sesame oil processing plant that suits your needs mostly, please contact our engineers to get customized solutions!

Sesame Oil Manufacturing Process

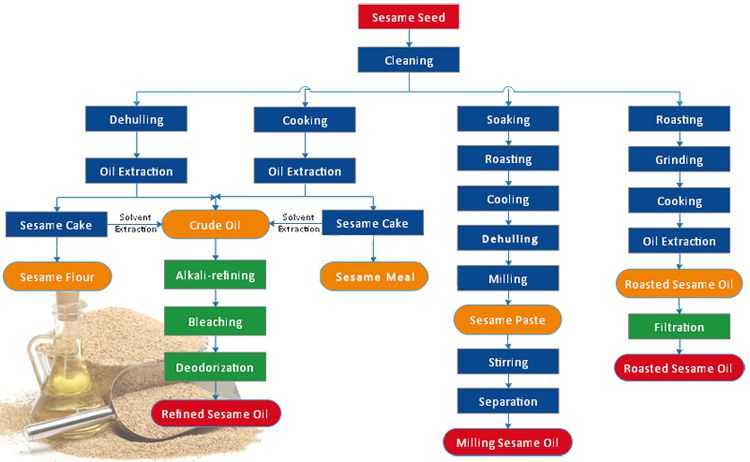

Sesame seed has rich oil content, it is a very great raw materials for vegetable oil in Asia, Africa and more. Sesame oil contains 41% linoleic acid, 39% oleic acid, 8% palmitic acid, 5% stearic acid and other fatty acids components. Since the long history of sesame oil, the sesame oil extraction technology has been continuously improved. The sesame oil manufacturing process is decided by the requirement for the sesame oil purposes. In today's market, the common Sesame Oil Manufacturing Process is as follows.

Common Sesame Oil Extraction Process

Sesame Seed Oil Types

There are generally two recognized types of sesame oil. The first one is refined sesame oil. Refined sesame oil and light refined sesame oil have a subtle color and flavor. It is used as a cooking oil and is relatively inoffensive, as the taste of the sesame in it is not overpowering. The second type is toasted sesame oil. Toasted sesame oil is more generally used in dressings or added at the end of a dish and has a powerful aroma of sesame seed. Most dark sesame oil is toasted, meaning that the seeds are submitted to high heat prior to extraction.

Production Process of Small Sesame Oil Factory

-

Cleaning of Sesame Seeds: In order to protect sesame oil extraction machine, ensure smooth sesame oil manufacturing process, improve the quality of sesame oil, it is necessary for any sesame oil factory to get the raw materials cleaned. It can be achieved by using professional cleaning equipment or destoning machine to get rid of the organic impurities and ironic impurities.

Cleaning of Sesame Seeds: In order to protect sesame oil extraction machine, ensure smooth sesame oil manufacturing process, improve the quality of sesame oil, it is necessary for any sesame oil factory to get the raw materials cleaned. It can be achieved by using professional cleaning equipment or destoning machine to get rid of the organic impurities and ironic impurities. - Softening of Sesame Seeds: This process is to soften the sesame seeds by adjusting its temperature and moisture for best flaking results. Generally, when the softening is done, the moisture is kept on 7% around and the temperature is about 47~50℃.

-

Cooking: In order to meet the oil pressing standards and get higher oil output and maintain the fragrances of sesame oil, cooking is the most common and effective manufacturing process to process the sesame seed flakes. Normally, there are many Auxiliary Cooking Equipment for this process, including electric cooker, steam cooking machine and more. Electric cooker is suitable for small or medium scale oil factory and steam cooker is more preferred by large scale oil processing plant.

Cooking: In order to meet the oil pressing standards and get higher oil output and maintain the fragrances of sesame oil, cooking is the most common and effective manufacturing process to process the sesame seed flakes. Normally, there are many Auxiliary Cooking Equipment for this process, including electric cooker, steam cooking machine and more. Electric cooker is suitable for small or medium scale oil factory and steam cooker is more preferred by large scale oil processing plant. - Sesame Oil Pressing: Since more and more people now pursue healthy living style, the mechanical sesame oil extraction method is now overwhelmed chemical solvent extraction. Screw Oil Press Machine is now the most popular and effective sesame oil processing machine. It squeezes oil out from the sesame flakes by mechanical forces instead of adding any chemical solvents. The main oil pressing part of screw oil press machine is the pressing rings and pressing bars that are installed in the pressing cage with scientific sequences.

Sesame Oil Manufacturing Machine for Sales (Capacity:1T/D ~20T/D)

For different customer’s requirements, our sesame oil extraction machine can be divided into 3 phases pressing and 4 phase pressing. The former is more suitable for hot pressing and the later is ideal for cold pressing. Surely, the whole sesame oil manufacturing process is decided by the actual oil processing requirements and specific oil pressing technology.

- Crude Sesame Oil Filtration: Generally, crude sesame oil is inevitable to have some impurities in the crude sesame oil that should be remove by Sesame Oil Filter. But, crude oil filtration can only remove the large organic impurities. High quality sesame oil should be refined by professional refining machinery to remove smaller solid impurities, free fatty acids, phospholipids, colloid, wax, pigment, odors and others.

- Sesame Oil Refining: The Edible Oil Refinery normally includes degumming, deacidification, decolorizing and deodorizing. Through professional oil refining process, the final sesame oil is guaranteed high quality, which makes it more favorable for human body.

Small Sesame Oil Refining Machine (Capacity: 1~20TPD)

- Sesame Oil Filling and Packing: oil filling and packing is recommended for a professional sesame oil processing plant, since through this process, the sesame oil can be directly sell in the market.

From above sesame oil manufacturing process, it is pretty clear about how to start an oil processing factory for sesame oil. The main equipment involved into the whole sesame oil manufacturing are cleaning machine, cooking machine, screw oil press, oil filter equipment and oil refinery machinery.

How Much Needed to Setup a Sesame Oil Processing Plant?

The biggest concern for our customers is the cost. Actually, this is a complicated. The cost is always closely linked with the capacity, technology, machinery, process and other factors. The price varies greatly. For a mini small scale sesame oil processing plant, the investment may cost around $8,000 and higher than that. We are professional manufacturer and supplier of various vegetable oil processing machinery, we are experiences in saving the cost and maximizing the economic profits. However, it is not the irrevocable equipment selections. Based on actual production conditions and requirements, our professional engineers will offer a BEST sesame oil processing plant for you! Any time you feel interested in our products, please contact us!

- I need a small fully automated sesame oil production plant which can give a capacity of nearly 10 kg per hour or nearby.

- If you are planning to set up mini mustard oil mill plant in your village for home use or business us, it is a great choice to try the automatic mustard oil extraction machine that takes up small space. More importantly, it is equipped with oil filter machine for oil purification. For more detailed information, please contact us directly. There are various types and models available for a mini oil mill.

-

Dear All,

We have a project to install a cotton seed cake production, soybeans cake, sesame oil plant and we want to know what kind of machine you can offer us. - Thanks for your questions. We can supply all the equipment for cottonseed oil, soybean oil and sesame oil production, including seeds pretreatment equipment, oil extraction equipment, oil refinery equipment, oil filling machine, oil packaging machine, etc.. In addition, we will offer customized design and plan for the oil production plant to help you minimize the investment cost and maximize oil efficiency.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)