What’s Crude Edible Oils? What's Edible Oil Refining?

Crude Edible Oils is an item given to the vegetable oils directly obtained by mechanical pressing or solvent extraction. The main ingredient of crude oils is a mixture of triglycerides, known as neutral oil. In addition to the neutral oil, the crude oils also contain a glyceride substance, collectively known impurities. The type, nature, status, can be roughly divided into mechanical impurities, fat-soluble impurities and water soluble impurities such three categories. (You may also like Cost Setting up Edible Oil Plant >>)

Edible Oil Refining is a general term for the removal of solid impurities, free fatty acids, phospholipid, colloid, wax, pigment and odors in vegetable oils. The presence of impurities contained in crude oils not only affects the use value, the safety storage of crude oil, but also cause difficulties for the deep processing crude oils. Edible oil refining is not only removes all the impurities out from the crude oils, but also refines harmful impurities, such as, gossypol, protein, lecithin, mucus, water and more. In this way, the edible oils can have better storage, industrial applications and cooking purpose. However, some beneficial substances, such as tocopherol, sterol and more, will be maintained. That is why edible oil needs oil refining process. According to different requirements and USES, the unnecessary and harmful impurities are removed from the oil to obtain refined oils and pure oils. (You may also like Cooking Oil Production Line >>)

Reliable Edible Oil Refining Machine Plant Manufacturer

ABC Machinery is the specialist in designing and manufacturing edible oil refinery equipment that can refine crude oil for edible or other purposes. We are also the BEST exporters of complete edible oil refinery plant. Featured lower operating cost and higher efficiency, all our clients spoken highly of the edible oil refining plant we designed and built. It can process many crude oils, including vegetables oils and animal oils, such as canola, cottonseed oil, palm kernel oil, coconut oil, seal oil, fish oil and more. (Related Post: Soybean Oil Refinery Plant >>)

Small Oil Refining Plant ABC Machinery Built Worldwide

Until now, we have helped our customers to establish edible oil refinery plant with different capacity in at least 30 countries, such as Australia, India, Bangladesh, Philippine, Korea, Jamaica, Zambia, Chile, Afghanistan, Nigeria, Tanzania, Togo, Kazakhstan, and more. We can offer the edible oil refining plant in batch type from 1 tons to 30 tons per day, while, the continuous edible oil refinery plant is up to 500 tons per day. (See more about Edible Oil Refinery Project Report >>)

Small Edible Oil Refining Plant Advantages

Small scale edible oil refinery plant is especially popular in today’s oil making market, since it has many outstanding features. For most investors or starters, it is definitely a great choice to start your edible oil making business. (Read more about Mini Oil Refinery Plant Cost >>)

- It has all functions of oil refinery, but requires less investment cost and less land occupation

- It is easy to operate and maintain, very suitable for small or medium oil production plant

- It is suitable for various crude oils, including cottonseed oil, peanut oil, soybean oil, palm kernel oil, palm oil, sunflower oil, rapeseed oil, mustard oil, fish oil, seal oil and more.

So, what is the edible oil refining cost. In fact, as a responsible supplier of edible oil refining machine, we are explicit that the EXACT cost of the edible oil refinery machine is decided by various aspects, including capacity, oil property, requirement for final produced oil, local market, etc. The Edible Oil Refining Plant Cost in small scale level ranges $21,000~$115,000. For more specific cost, please directly contact us. Our professional engineers and sales will takes all your requirements into consideration and offer you custom edible oil refining plant and corresponding cost.

Edible Oil Refining Plant Types

Edible Oil Refining Plant Types

- Batch Oil Refinery - 1~30TPD

Batch oil refinery is more suitable for small oil refining line since it has many outstanding advantages. The whole refining equipment takes less areas, the investment cost is relatively lower, and it can refine almost all the crude edible oils. The main refining process of batch edible oil refinery plant include degumming, neutralizing, decolorizing and deodorizing. The capacity of batch edible oil refining plant is 1TPD to 30TPD.

- Semi-continuous Oil Refinery - 10~50TPD

Semi-continuous oil refinery can fit small scale and medium scale edible oil refining plant. It is efficient and can be designed based on customer’s requests. The common daily capacity of semi-continuous edible oil refinery plant is from 10 TPD to 50 TPD. It also can process a variety of crude oils, including crude plant oils and animal oils.

- Continuous Oil Refinery - 30TPD Above

Continuous oil refinery is designed for large scale edible oil refinery plant. The daily capacity of continuous type refining is generally over 30TPD. It carries out continuous and completely automatic refining process for highest efficiency. It has high requirements on all the basic conditions for an edible oil refining plant.

Edible Oil Refining Plant Capacity

Cooking Oil Refining Method

- Mechanical Method

Mechanical refining, including precipitation, filtration, centrifugal separation, is mainly used to separate mechanical impurities and a part of the gel soluble impurities suspended in the crude oil.

- Chemical Method

Chemical refining mainly includes acid refining, alkali refining, lipidization, oxidation and so on. Acid refining is treated with acid, which mainly removes pigment, colloidal soluble impurities; Alkali refining is treated with alkali, which mainly removes free fatty acids; Oxidation is mainly used for decolorization.

- Physical & Chemical Method

Physical and chemical refining methods mainly include hydration, decolorization, steam distillation and more. Hydration mainly removeS phospholipid, decolorization mainly removeS pigment, steam distillation is to remove odor and free fatty acids.

Edible Oil Refining Process

The edible oil refining equipment ABC Machinery provide is suitable for refining all kinds of crude vegetable edible oil, such as rice bran oil, peanut oil, soybean oil, sunflower oil, palm oil, palm kernel oil, cottonseed oil, olive oil, mustard oil, coconut oil, etc. In addition, it can also effectively refine the impurities contained in the edible animal oils, such as seal oil, fish oil, chicken oil, etc. The specific oil refining process for edible oil are detailed below.

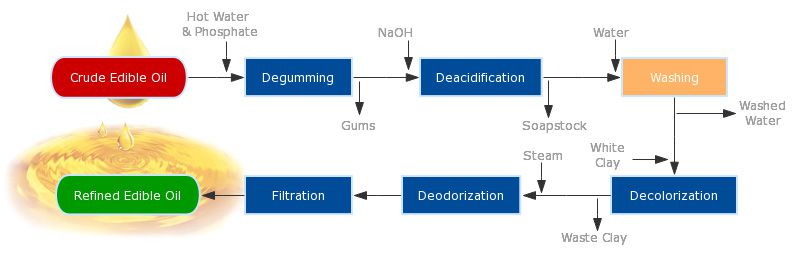

Edible Oil Refining Process Flow Chart

- Degumming Stage

In the edible oil refining process, removing colloidal impurities from crude oil can be completed by physical, chemical or physicochemical methods, which is called degumming.

hydration degumming is a very important step. The amount, temperature and speed of water added with phosphoric acid are all important. Through the principle of glue flocculating when it meets water, the glue is precipitated.

- Deacidification Stage

The stage makes use the sodium hydroxide (NaOH) to neutralize free fatty acids in the crude edible oil, during which some soap will be produced and separated from the oil. Lye not only neutralizes free fatty acids, but also neutralizes excess phosphoric acid. In the process of batch and semi-continuous edible oil refining, we use the method of precipitation to separate soap feet. But in the full continuous refining process, we use a centrifuge to separate the soap, which is more efficient.

- Decolorization Stage

Since the crude oil contains pigment, the color of the oil will be darker. In order to improve the color of oil and obtain higher quality edible oil, we need to use media, such as activated clay, to absorb pigment, and then use vibration filter to separate the waste clay.

- Deodorization and Dehydration Stage

The smell of the crude oil is not very good, which will affect the storage and selling price of the oil. Therefore, we usually adopt direct steam to remove the smell of the crude oil. The oil also contains 0.5% water, which is removed by the high temperature in the deodorizer.

- Filtration Stage

After obtaining deodorant oil, we will use stainless steel precision filter (safety filter) to filter again to ensure the quality of oil.

- Dewaxing Stage

Some vegetable oils contain wax, such as sunflower oil, corn germ oil and rice bran oil all. So, dewaxing is necessary if you want to get first grade edible oil. This stage is optional according to the user's requirements.

ABC Machinery has gained rich practical experiences in setting up edible oil refinery plant, especially in small scale. Choose us, you can get the most efficient edible oil refinery machinery, the advanced oil refinery technology, as well as the most competitive price. Our professional engineers will offer you customized plan. If you prefer to know more information, please get in touch with us at anytime!

-

Hi, I would like to enquire on mini oil refinery plant for crude palm oil.

How much will it costs? What are the expenses incurred? What are the end products? What is the fixed and operating expenses regarding the machines? Thanks -

Dear sir/madam,

1) The cost of mini oil refinery plant is decided as your requested capacity.

2) Generally, the end products are high quality refined edible vegetable oil. However, the specific oil refining process can be customized for different vegetable oil purposes.

3) As for the fixed and operating expenses of the edible oil refining machines, it is hard to offer the exact cost since it is all decided by the capacity, local labor cost and other factors.

4) Detailed capacity and price lists have sent to your email inbox, please check it in time. Any other questions, please do not hesitate to contact us. - Dear sir, I want to start a business here in my country to sell refined edibles oils. The capacity of edible oil we want to get is per a 1t/8hour.we would like to refine all kind of oils. We want to manufactured by stainless steel. Please inform us how much will cost this refinery of 1t/8 hour without of course the cost of shipping. Thanks in advance.

-

Hello, sir. Thanks for your inquiry and questions.

1) Our edible oil refinery machinery is suitable for various vegetable oils and animal oils and fats, including coconut oil, palm oil, soybean oil, peanut oil, sunflower oil, seal oil, chicken fats and more.

2) We can provide the custom-made stainless-steel oil refinery equipment, but the cost is usually higher than the normal oil refinery machines that are made of carton steel.

3) As for the shipping cost and process, due to the price fluctuation, the final cost shall be subject to the market price at the time of loading the goods.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)