Undertake 1~5 ton/day Crude Oil Refinery Plant Design and Construction

Factory Layout and Machine for Min/Small Oil Refinery Plant

- Capacity: 1~5 Tons per Day

- Application: Vegetable Oils (Crude Sunflower Oil, Crude Soybean Oil, Crude Palm Kernel Oil, Crude Palm Oil, Crude Mustard Oil, Crude Castor Oil, Crude Groundnut/Peanut Oil, Crude Sesame Oil, Crude Canola Oil, Crude Coconut Oil, etc); Animal Oils (Crude Fish Oil, Crude Seal Oil, etc.)

- Service: Installation & Commissioning; Operator Trainnig, etc.

- Materials: Carbon Steel, Stainless Steel or Customized

ABC Machinery is a modern enterprise that is engaged in oil processing equipment for at least two decades. We have independent research and development, manufacturing, installation, debugging, technical team to provide better service for customers. If you are planing to start your own edible oil mill business, we not only have high quality and factory price equipment, but also the practical and technical experiences that can share with you!

Edible oil refining, the most important section of a complete vegetable oil production line, can't be ignored. Mini Oil Refinery Plant is the No.1 choice for small or medium scale oil mill plant to improve the oil quality and reduce the oil production cost. Here, we will help you gain the complete knowledge about edible oil refinery plant, including its functions, working principles, production process, setup cost, machines required and more. (Related Post: Edible Oil Manufacturing Plant Cost >>)

Mini Crude Oil Refinery Machine Functions

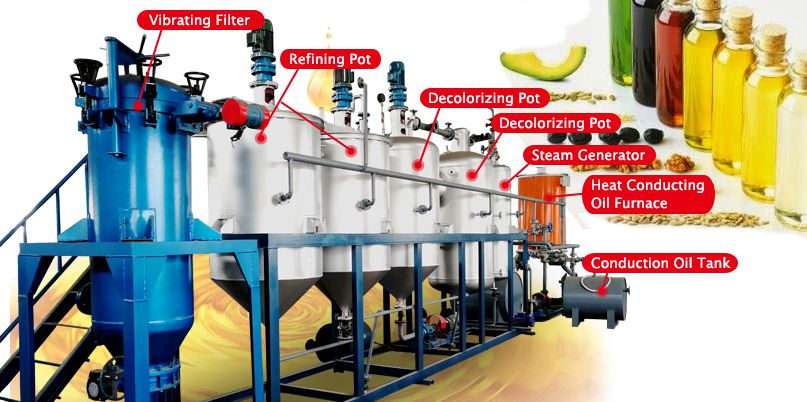

Mini Oil Refinery Plant

Mini oil refining plant is a type of very small oil production line that maintains all the functions and merits of medium and large scale oil refinery plant. At the same time, it features small investment cost, less land occupation and quick returns, which makes mini oil refining line is especially ideal for small and medium oil mill plants. If you there are any needs, please contact us for detailed specifications and small edible oil refining plant cost!

Mini/Small Oil Refinery Plant Setup Cost

The main cost to setup mini or small scale oil refinery plant mainly include three parts, the equipment cost, transportation cost, installation and commission cost. A reliable mini oil refinery machine supplier will help you a lot on reducing the total cost, since most of the reliable suppliers will help you to find cheap and reliable shipping company. And, it they have rich experiences, they will short the installation and commissioning period and ensure normal operation. As for the equipment cost, different capacity and supplier have different price. If you want to know the exact price of our mini oil refinery plant, please contact us directly and tell us your specific requirement, then we can offer customized equipment unit and detailed quotation!

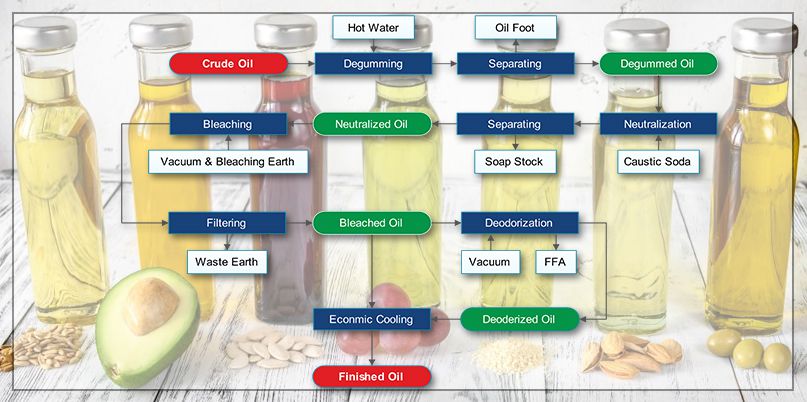

Mini Oil Refining Plant Working Process

Edible Oil Refining Process

- Degumming: the process to remove gelatinous impurities within crude oils by chemical or physical methods is called degumming. In edible oil, if the content of phosphatide is high, it is easy to blister, smoke and smell when heated. And the phospholipid is oxidized at high temperature and then make the crude oils in dark brown, which affects the flavor of fried food. Based on the principle that phospholipid and some proteins within the crude oils are soluble to oils at the condition of sewage, but insoluble in oil and water after the formation of hydrate, degumming process is to add hot water or steam into crude oils, and heat crude oils, agitation mix at the temperature of 50 ℃. Then let stand for layered, in that way, the phospholipids and part of the proteins are removed from the crude oils.

- Deacidification: the Free Fatty Acids (FFA) contained in the oils will affect its stability and flavors. The process to remove FFA is called deacidification or alkali refining.

- Decolorizing: crude oils may contain chlorophyll, carotenoid and other pigments. Chlorophyll is photosensitizer, which affects the stability of oil, while other pigments can affect the appearance of oil. So theses pigments can be removed by adsorbent in decolorizing process

- Deodorization: there are some undesirable odor substances in oil, mainly from oil oxidation products. The method of vacuum distillation was used to inhibit the oxidation.

How to Set up Mini Oil Refinery Plant (1~5T/D)

It is actually easy to set up a mini oil refinery plant. Choose the right factory location, ensure enough raw material supply, integrated useful resources and find out a reliable oil refining plant supplier. ABC Machinery has rich experiences in setting up oil refinery plants. And, we have built many mini oil refinery lines for clients at home and abroad. (See more information at Oil Refinery Projects>>) Here, we listed some of the mini oil refinery plant we built in the world. If you want to know more information, please contact with us, we can offer what more than you expect!

Mini Oil Refinery Machine Setup

Project Report: Mini/Small Edible Oil Refining Plant ABC Machinery Built

| No. | Project Report | Location |

|---|---|---|

| 1 | 10TPD Soybean Oil Extraction & 1TPD Soybean Oil Refinery Plant | Nigeria |

| 2 | 5TPD Mustard Oil Milling & 1TPD Mini Mustard Oil Refining Line | India |

| 3 | 3TPD Fish Oil Refining Plant | Bangladesh |

| 4 | 10TPD Soybean Oil Refining Plant | Jamaica |

| 5 | 10TPD Sunflower Oil Production & 3TPD Sunflower Oil Refinery Project | Moldova |

| 6 | 10TD Cottonseed Oil Refining Plant | Afghanistan |

| 7 | 5TPD Coconut Oil Refinery Plant | Philippines |

| 8 | Lab-scale Seal Oil Refining Unit (Custom-made) | United States |

| Remark | If there are any needs for crude edible oil refining, please just massage us your requirements, we will quickly offer the customized mini crude oil refinery plant cost! | |

Buy Mini Oil Refinery Machine from ABC Machinery

How to Setup 1~5TPD Mini Oil Refinery Plant with Ease and Low Cost? Factory Price Oil Refining Machine for Edible Oil Production: buy edible oil refinery plant from professional oil refining equipment manufacturer or supplier at factory price, get FREE technical instruction of edible oil refining process and business plan to set up edible oil refinery project in Mexico, Panama, Pakistan, Thailand, Kazakhstan, etc., at low cost.

Mini Oil Refinery Plant Features

- Small investment and quick returns.

- Low energy consumption and small footprint.

- High quality refined oil can be used for edible or industrial use.

- Compact structure and beautiful layout.

- Simple structure and convenient operation.

- Perfect after-sales service

Yes, we can provide the complete soya bean oil processing plant for you, from soybean treatment, soybean oil extraction, refinery, bottling and packaging. Please tell us your expected capacity, so we can offer the exact cost for you.

- Hi good day. Our company is in to the cultivation and processing of Crude palm oil and Palm Kernel oil, located in Nigeria. We are interested in scaling up to the production of Edible refined vegetable oil (Olein and stearin.) Our intent would be to replicate one of your 1TPD - 5 TPD “mini oil” refineries in Cote D’vore. Can we use the same refinery for Crude palm oil and Palm kernel oil, and what is the price for the different sizes of your oil refinery?

- Hello, dear. I am happy you find us. We have set up an edible oil refining and fractionation plant in Cote D’vore. It exactly can produce the Olein and Stearin. Our engineers will send you a customized palm kernel oil refinery plant, altogether with the price list for you reference.

- I am interested in the mini soya bean oil processing/refining and bottling machines.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)