Purchase Right Coconut Oil Expeller Press from ABC Machinery

Working Principles of Coconut Oil Expeller and Screw Press Machines

Coconut oil extraction involves mechanical separation of oil from dried coconut meat (copra) using an expeller press system. In modern coconut oil extraction facilities, the coconut oil expeller pressed method is preferred for its ability to maintain oil purity and achieve yields up to 65–70% from high-quality copra.

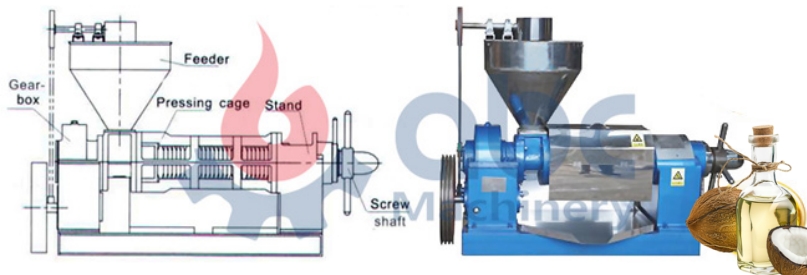

Internal Mechanism and Compression Process

A screw press mechanism converts rotational motion into continuous pressure. The copra is fed into a barrel with a rotating screw shaft, where it undergoes gradual compression. The pressure inside the press chamber can reach 40–60 MPa, while the temperature varies between 80–120 °C in hot-press operations. These parameters directly affect oil yield and residual oil content, typically reducing residuals below 8% in optimized setups.

| Parameter | Typical Range | Effect on Yield |

|---|---|---|

| Screw Speed | 20–35 rpm | Higher speed lowers yield by 3–5% |

| Barrel Pressure | 40–60 MPa | Increases extraction efficiency |

| Temperature | 80–120 °C | Enhances oil flow, reduces viscosity |

| Moisture Content | 5–7% | Optimal for consistent oil quality |

| Residual Oil in Cake | ≤ 8% | Indicator of extraction efficiency |

Small Coconut Oil Screw Press Machine Working Principle

Become Our Regional Distributor for Small Oil Press Machines

We are now looking for reliable and motivated partners worldwide to join us as regional distributors for our small oil press machines. If you have experience in agricultural machinery sales, local distribution networks, or are passionate about promoting efficient oil processing solutions, we welcome you to collaborate with us.

As our authorized agent, you will enjoy:

- Exclusive regional sales rights and competitive pricing policies

- Comprehensive technical and marketing support from our professional team

- Stable product supply and high-quality equipment recognized by global users

Join us in expanding the global market for small-scale oil production equipment and share the growing success in the edible oil processing industry. Contact us today to learn more about partnership opportunities in your region.

Influence of Temperature and Pressure

Temperature control is critical. Overheating above 130 °C may degrade fatty acids and color quality. Conversely, low pressure below 35 MPa reduces extraction efficiency by up to 10%. Proper calibration ensures that energy consumption (around 35 kWh/ton) remains within industrial benchmarks while maintaining high throughput.

Cold Press vs Hot Press Comparison

- Cold Pressed Coconut Oil: Extracted below 60 °C, retaining natural antioxidants, with oil yield averaging 55%. (Related Information: Cold Pressed Oil Machine>>)

- Hot Pressed Coconut Oil: Involves preheating copra, achieving yields up to 70%, suitable for industrial-scale production.

- Pressure Balance: Optimized at 50 MPa for continuous operation.

- Screw Configuration: Multi-stage compression ensures steady oil discharge.

- Filtration System: Integrated mesh filters reduce impurities to below 0.1%.

How to Select the Right Coconut Oil Expeller Equipment

Select the Appropriate Model of Coconut Oil Extractor Based on Your Specific Needs.

Selecting the proper coconut oil expeller pressed machine depends on production capacity, power rating, and raw material properties. Equipment sizes vary significantly — from 20 kg/h for pilot systems to 20 ton/h for full-scale coconut oil plants.

Key Technical Parameters

When evaluating screw press machine specifications, focus on three primary aspects:

- Motor Power and Torque Output – Typically between 7.5 kW for small units and 75 kW for industrial systems.

- Screw Diameter and Pitch Ratio – Determines compression efficiency and throughput.

- Oil Yield Rate – Industrial systems should consistently achieve >65% yield.

For factories processing multiple oilseeds (coconut, palm kernel, sesame), choose modular expellers with interchangeable screws and barrels. These systems handle feedstock moisture variation between 4–8% without yield loss, offering versatile operation across different oil types.

Comparison of Manufacturers and Material Grades

Evaluate machine construction — hardened steel (38CrMoAlA) screws and double-layer barrels withstand 15,000 hours of continuous use. Always compare suppliers on:

- Operational Efficiency (%)

- Energy Consumption (kWh/ton)

- Maintenance Cycle (hours)

Matching the expeller’s configuration to plant capacity ensures sustainable ROI and consistent oil quality. Get your customized coconut oil expeller press selection plan — contact our industrial solution specialists today.

Optimizing Oil Extraction Efficiency and Operational Stability with Advanced Machinery

Maintaining consistent oil output requires precise control of raw material and process parameters. To optimize coconut oil extraction efficiency, engineers must manage drying temperature (70–80 °C) and feed particle size (5–8 mm). Proper preheating reduces moisture to 6%, improving oil flow by 8–10%.

- Feed Uniformity: Reduces screw torque fluctuation by 12%.

- Screw Speed Adjustment: Lowering speed from 35 rpm to 30 rpm can increase oil yield by 3%.

- Preventing Clogging: Install reverse-flow cleaning rings.

- Maintenance Routine: Schedule bearing lubrication every 300 hours and wear inspection every 1,000 hours.

Small operational changes can translate into substantial efficiency gains in industrial-scale extraction lines. Partner with us to implement data-driven optimization strategies that keep your coconut oil screw press at peak performance.

Coconut Oil Making Machine Investment and Maintenance Cost Control Strategies

The total coconut oil press machine cost analysis covers capital investment, power consumption, and spare part replacements. A standard 10 ton/day expeller line may cost USD 35,000–50,000 initially, with annual maintenance around 4–6% of total investment. Energy usage typically averages 30–40 kWh per ton of copra processed.

Large Coconut Oil Press Machine in the Industrial Extraction Factory

Efficient maintenance scheduling extends machine life beyond 10 years. Replacing wear components (screws, rings, bearings) every 2,000–3,000 hours minimizes unplanned downtime. ROI optimization comes from combining low energy design with automation control — yielding payback within 18–24 months.

Maximize your oil plant’s ROI — connect with our project engineers to design a cost-efficient expeller maintenance strategy.

By integrating advanced coconut oil expeller pressed systems into modern coconut oil extraction facilities, manufacturers can achieve higher yield, energy savings, and long-term profitability across global production sites.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)