Start Cold Pressed Peanut Oil Production Business

Cold pressed peanut oil, produced under low-temperature conditions, retains the natural aroma and nutrients of peanuts to the greatest extent. With the trend of consumption upgrading, it has been increasingly valued in recent years. Many investors, processing factories, and even catering businesses are now asking: How is cold press oil extraction different from traditional hot pressing? Why is it positioned as a “premium” product in the market?

Read More: Cold Pressing for multiple oils Extraction>>

This article will provide a detailed breakdown of the cold pressing oil process, cold pressed oil machine selection and comparison, helping readers make clearer decisions when planning oil production business or buying equipment.

Differences Between Cold Pressed Peanut Oil and Regular Peanut Oil

In peanut oil production, “hot pressing” and “cold pressing” are not only about temperature but also reflect different product market positioning and processing strategies.

First, looking at oil extraction process conditions:

- Hot pressing is usually carried out at temperatures above 120℃. The raw material undergoes cooking and crushing before entering the oil press machine. High temperature improves the oil yield and reduces viscosity but destroys part of the natural nutrients.

- Cold pressing is performed below 60℃, and some specialized cold oil press machines can maintain temperatures around 40℃. Under these conditions, vitamin E, unsaturated fatty acids, and natural antioxidants in peanuts are preserved. However, the oil flowability is reduced, and the oil yield is significantly lower than hot pressing.

Then, considering finished oil quality:

- Hot pressed oil has a golden color and a strong aroma, making it suitable for mass catering and daily home cooking.

- Cold pressed peanut oil is lighter, clearer, and has a more delicate taste. It is often seen as a “premium oil” with advantages in high-end retail or gift markets.

Finally, comparing production cost and return:

- Hot pressing has a high yield of 40%–45%, with lower residual oil, making it more suitable for large-scale continuous production.

- Cold pressing usually achieves only 30%–35% yield, with higher residual oil, which increases unit costs. However, its premium market value compensates for this gap. For instance, a 500ml bottle of cold pressed peanut oil can retail 30%–50% higher than regular hot pressed oil in many markets.

In reality, vegetable oil cold pressing and hot pressing are not mutually exclusive but cater to different consumer groups and value chains.

Cold Pressed Peanut Oil Extraction – How Every Process Step Maintains Low Temperature

The key to cold press oil extraction lies in temperature control. Throughout the cold pressed peanut oil production line, maintaining a low temperature is crucial for preserving natural nutrients and active compounds. The entire processing plant must follow strict temperature strategies from raw material pretreatment to pressing and post-processing.

Raw material pretreatment stage must avoid overheating: Peanut kernels are cleaned and then dried at ≤45℃ to reduce moisture to 6%–8%. This is achieved with low-temperature drying equipment such as heat pump dryers or low-heat airflow systems. Crushing and flaking require low-speed milling equipment (≤300 r/min), combined with cooling water circulation (15–20℃) to absorb frictional heat, ensuring material temperature stays below 35℃.

Pressing stage is the technical core: Cold press oil extractors must use specially designed press chambers and screws. By lowering screw angles (≤12°) and controlling speed (15–25 r/min), frictional heat is minimized. The press chamber is equipped with a temperature-controlled cooling jacket, circulating liquid (20–25℃) to stabilize internal material temperature at 40–50℃ (maximum ≤60℃). Real-time infrared thermometers and PLC systems monitor and adjust cooling flow, forming a closed-loop temperature control mechanism.

Post-processing stage also requires low temperature: Filtration is carried out by plate-and-frame or centrifugal filters at ≤40℃, avoiding vacuum heating. Stainless steel storage tanks with insulation layers maintain oil at 10–15℃, slowing oxidation and preserving the natural flavor and nutritional value of cold pressed peanut oil.

Choosing the Right Cold Press Oil Machine for Peanuts

Which cold press oil machine is right for your business? The equipment should match production scale, product positioning, and investment budget, rather than simply being the expensive option.Currently, the market offers three main categories of cold press oil machines, each suitable for different production projects:

As a leading cold pressed oil machine manufacturer and supplier, ABC Machinery can provide high-quality cold pressed peanut oil machines tailored to your needs. Contact us for a quick quote with machine parameters and detailed cold press oil machine price!

Spiral Cold Press Oil Machine – Cost-effective option for continuous production

Widely applied in peanut oil processing, this equipment uses a progressive screw press for continuous feeding, pressing, and residue discharge. A single unit can process hundreds of kilograms to several tons per day, ideal for small to medium oil mills (1–5 tons/day).

Screw oil press machine does not require additional heating. By reducing the rotational speed (15-30 r/min), the oil temperature is maintained at approximately 40-50°C, achieving an oil yield of 38-42%. Featuring high automation and low labor costs, it is suitable for small-scale commercial or home-based cold-pressed peanut oil production.

Small Cold Press Oil Machine at Factory Price

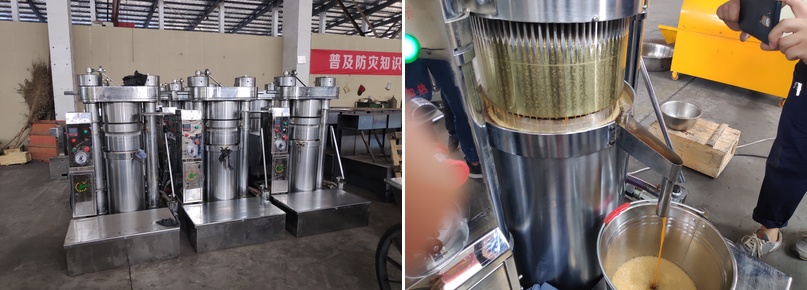

Hydraulic Cold Press Oil Machine – Batch processing with maximum nutrition retention

Using static high-pressure (30–60 MPa), hydraulic cylinders press oil cakes slowly and evenly, maintaining very low temperature (≤40℃). This preserves heat-sensitive compounds such as vitamin E and sterols. Suitable for small farms, home businesses, and organic peanut oil producers. The machine is simple, low-maintenance, but requires manual feeding and discharge.

Buy Hydraulic Cold Press Expeller for Peanut Oil Extraction

Specialized Cold Press Machine – Advanced intelligent temperature control

Designed specifically for cold press oil extraction, this machine combines spiral pressing with multi-stage cooling (water + air). Equipped with variable frequency control and intelligent temperature modules, it adjusts parameters according to peanut variety. Oil yield is 2–3% higher than regular spiral machines, with lower acid values (≤0.8 mgKOH/g). It is ideal for premium edible oil and cosmetic-grade oil production but requires higher initial investment. Suitable for large-scale factories with output over 5 tons/day.

Large Cold Pressed Oil Machine for Sale Shipped to Tunisia

Key factors when selecting equipment:

- Match capacity with available space (e.g., hydraulic presses require cake preparation area).

- Ensure temperature accuracy (real-time monitoring & closed-loop cooling).

- Verify oil quality protection (press chamber materials must meet food-grade standards).

- Consider downstream needs (low-temp filtration, dewaxing).

| Equipment Type | Core Principle | Daily Capacity | Pressing Temp | Peanut Oil Yield | Automation | Typical Use Case | Cost (Approx.) | Key Advantages | Main Limitations |

|---|---|---|---|---|---|---|---|---|---|

| Spiral Cold Press Oil Machine | Continuous screw pressing | 1–5 tons | 40–50℃ (≤60℃) | 38–42% | High | Home workshops, Small factories, commercial use | $8,000–$11,000 | Efficient, low labor cost | Slightly higher friction heat |

| Hydraulic Cold Press Oil Machine | Static hydraulic high-pressure | ≤1 ton | ≤40℃ | 35–39% | Low | organic oil production | $4,000–$20,500 | Best nutrition retention, low temp | Low capacity, not continuous |

| Specialized Cold Press Machine | Multi-stage screw + smart cooling | ≥5 tons | 35–45℃ | 40–44% | High | Premium edible/cosmetic oil production | $20,000~ | Higher yield, stable oil quality | High initial investment |

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)