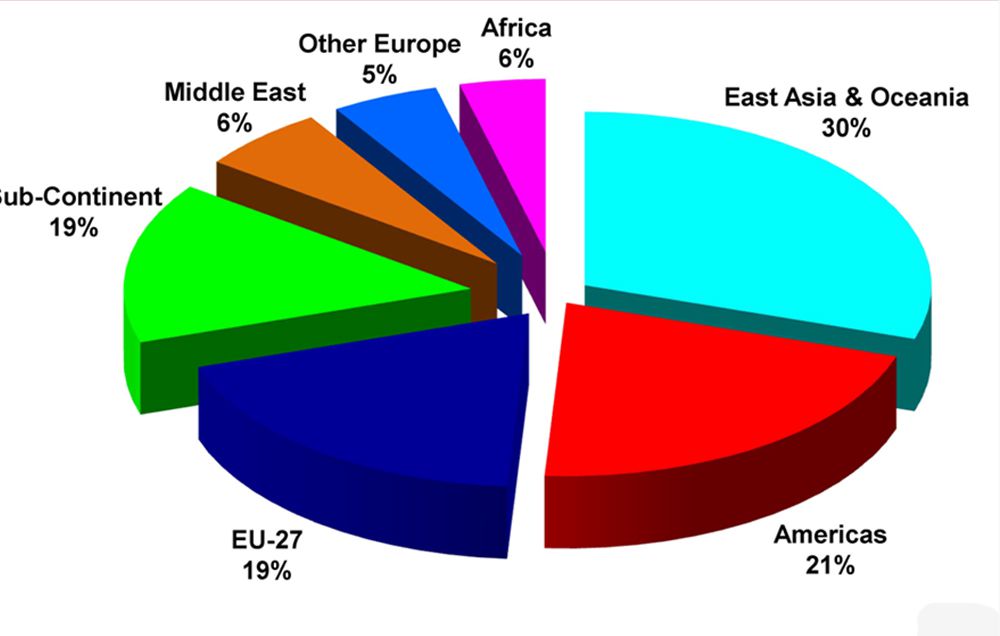

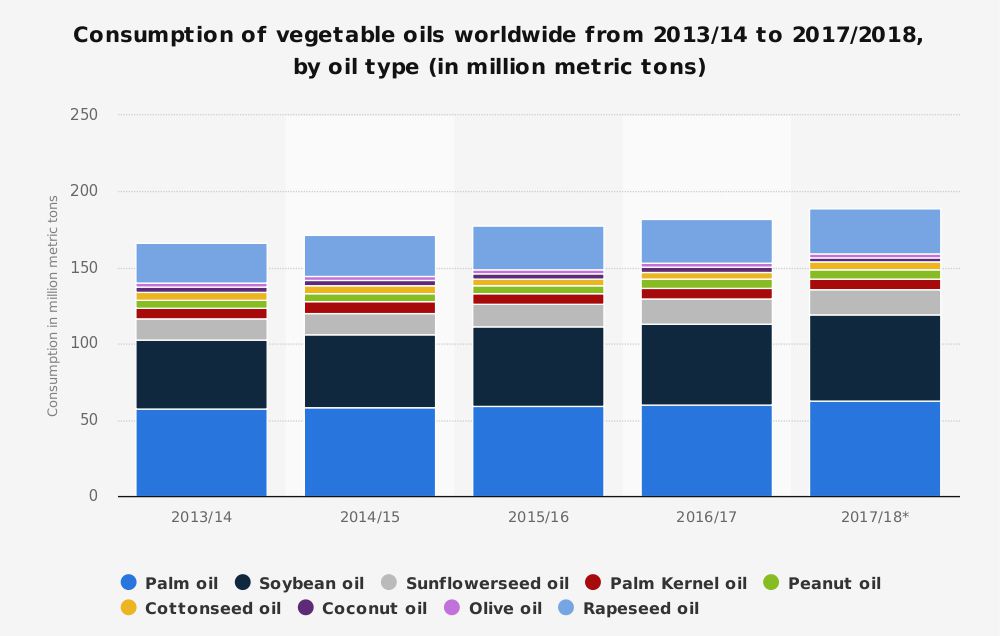

The process of producing edible oil is usually completed within a vegetable oil extraction plant. Vegetable oil has become increasingly important as animal fats have lost share in the market. The increase of importance has been particularly relevant to palm oil and soybean oil. But it has also been significant for other vegetable oils, such as rapeseed oil, sunflower oil, groundnut/peanut oil and more. With regard to the use that vegetable oils, it is rather obvious in the utilization in the food industry. But, it is also used for the production of many industrial products, such as soap, health care products, biodiesel oil and more.And, it is also worth noticing that the byproduct of vegetable oil extraction are used for animal feed purposes.

Various Seeds and Nuts to Make Vegetable Oils

Customized Small Vegetable Oil Extraction Plant at Factory Price

ABC Machinery is expert in vegetable oil processing. We not only provide high quality oil extraction machinery to process various vegetable nuts and seeds, but also offer customized vegetable oil production business plan for you to establish your own vegetable oil extraction plant. Small size vegetable oil production line is now the hottest product catalogue in our company due to the huge market potentials. For most investments or businessmen, small size oil extraction plant can be a easiest way since it requires less investment cost but can ensure high profits. ABC Machinery offer custom-made small oil extraction plant for various vegetable seeds and nuts at factory lowest price!

Vegetable Oil Extraction Plants for Sales

Capacity ABC Machinery can Supply: 5TPD, 10TPD, 15TPD, 20TPD, 30TPD, 50TPD, 100TPD and above

Cost of Vegetable Oil Extraction Plant: the exact cost of vegetable oil extraction plant is decided by the capacity, equipment selections, oil extraction technology and more. For example, a 5 tons per day small scale oil extraction plant may cost $7,000 ~ $15,000.

Small Scale Vegetable Oil Extraction Plant Process

In order to produce vegetable oil, the vegetable oil extraction plant employs different methods depending on the types of seeds and nuts, the extent of the production. In general, the main process of small scale vegetable oil extraction plant that are regularly followed are pretreatment of seeds and nuts, crude oil extracting and oil refining. Some larger oil processing plant may also adopts solvent extraction for the residual oil cake after the mechanical oil extraction process.

- Pretreatment of Vegetable Seeds and Nuts

The initial steps in the process of vegetable oil processing consists of different actions that aim at removing impurities and improving the conditions of raw material (seeds and nuts) before pressing them. It is also a preparation to adequate the form of the material for extraction so that the desired capacity and extraction yield are achieved. It will therefore have impact on quality of the final product and on reducing production cost. The process of cleaning intend to eliminate organic and inorganic impurities. The industrial oilseeds processing machine that are commonly used in this process include cleaning sieves, dehullers, flaking mills, cookers, screw extrusion machines, dryers among others. (Read more about the Pretreatment Equipment for Oilseeds >>)

- Vegetable Oil Extraction

The traditional method for oil extraction is known as mechanical pressing. In this approach screw oil press machine is used to compress or squeeze the oil out from the vegetable seeds and nuts. With oil pressing the use of chemicals is avoided. A screw type oil extraction machine is used to press oil through a cavity. Friction and continuous pressure are the means employed to achieve oil extraction purpose. The basic design of screw vegetable oil extraction machinery has evolved with considerable improvements so that modern presses exhibit enhanced capacities with controlled residual oil levels. One of the specific advantages of expeller pressing is the possibility of having continuous mechanical extraction of oil not being affected by the scale of the operation. Considering the equipment necessary for vegetable oil pressing, the oil expeller press is actually the main component of oil extraction process. However depending on the capacity and taking into account the working principle, vegetable oil extraction machines can be classified as screw oil press and automatic oil press machine.

- Crude Oil Refining

For several reasons, vegetable oil demand has increased during the last years. In the case of edible oil or even for some technical applications, there have more requirements for vegetable oil processing, the nutritional oil quality and the sustainability is also important in terms of reduction of aids and chemicals. The vegetable oil refining techniques for edible oils can be divided into chemical or physical oil refining. The techniques selected depend on the type and quality of the crude oil that is going to be processed. This refining process in a complete edible oil plant is performed by a series of actions described in the following lines.

- Degumming, used to detach the gums, phospholipids, and proteins that are not soluble in oil when it is hydrated.

- Neutralization is the step employed for removing free fatty acids from crude oils.

- Bleaching, consisting of the actions for removing contaminants that affect the appearance and performance of the oil.

- Deodorization, comprising a distillation process for removing unwanted odor and taste. It has to be mentioned also the winterization stage for removing the higher melting point parts from oil.

The equipment required for vegetable oil refinery plant include neutralizers, bleachers, deodorizers, heat exchangers, and oil filters. It is important to emphasize that the quality of edible oil is characterized by its components and features. The incorporation of the described industrial processes aim at producing a colorless, odorless, and flavorless oil.

How to Start Vegetable Oil Extraction Business?

Setting up a complete oil mill plant for vegetable oil extraction is the most crucial step to start the vegetable oil business. But there are still many influencing factors that play an important role in starting vegetable oil extraction business and ensure it success. These factors include business strategy, raw materials supply, oil extraction plant location, running cost, operation staff, marketing and advertising of final produced oils, and more. In order to ensure the success of your business, above listed factors should be taken into consideration when you set goals in the vegetable oil processing industry.

Many vegetable oils are in great demand around the world, including soybean oil, sunflower oil, rapeseed oil, cottonseed oil, palm oil, palm kernel oil, rice bran oil, peanut/groundnut oil, coconut oil, and more

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)