In recent years, people's requirements for daily essential edible oils have become higher and higher, and they are no longer just realized in ordinary pressed edible oils. People require healthier and better-tasting refined edible oils to flood the market for selection. The refined soybean oil is clarified and free of impurities. It not only has beautiful visual effects, but also has high economic value. It has a refreshing taste and good storage stability.

Soybean Oil Refining Equipment Manufacturer

Many investors hope to invest in the edible oil processing plant, but they don’t know much about the industry, so today ABC Machinery will tell you about the basic working principles of small refining equipment, which can help you understand more. As for the deeper reasons for soybean oil refining, let's listen to the answer of equipment manufacturer ABC Machinery!

Introduction to the Reasons Why Soybean Oil Needs to Be Refined

As the name suggests, soybean oil refining refers to the process of using oil refining equipment to remove impurities from crude oil, extract essence, and purify it.

The impurities contained in unrefined soybean oil mainly include cake crumbs, peptized impurities, free fatty acids, pigments, and odor substances. The reason for refining is to reasonably filter out the cake crumbs, peptic impurities, free fatty acids, pigments and odor substances contained in the pressed or leached crude oil.Therefore, it is more suitable for edible and storage, and enhances the edible value and market value of soybean oil.

Comparison of Various Processed Oils

The presence of impurities in crude oil not only affects the edible value and safe storage of the oil, but also brings difficulties to the deep processing of soybean oil. The purpose of refining is not to remove all the impurities in the oil, but to remove the harmful and unhelpful impurities such as gossypol, protein, phospholipids, mucus, moisture, etc., and beneficial "impurities" , Such as tocopherols, etc. should be retained.

Specific Manufacturer Process of Small-scale Soybean Oil Refining

Soybean Oil Refining Technology

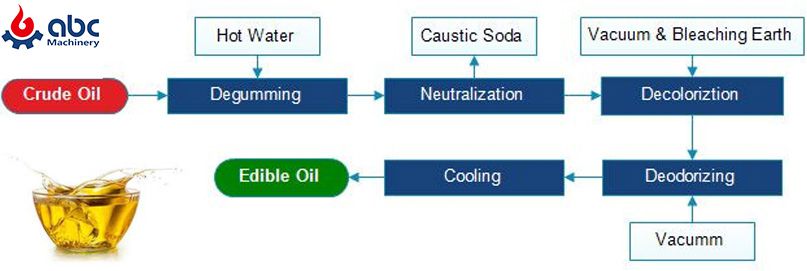

- Degumming process: remove peptic impurities such as phospholipids and proteins in the crude oil.

The peptic impurities are hydrophilic, and hot water or phosphoric acid is added to the caustic pot to make the peptic impurities swell, agglomerate and separate and remove. It can avoid emulsification in the deacidification process, thereby increasing the loss of auxiliary materials in the subsequent process. In addition, the undegummed oil cannot be physically refined and deodorized, and cannot be processed in depth.

- Deacidification process: Mainly remove free fatty acids in crude oil.

The content of free fatty acids will affect the quality, taste and storage time of the finished oil. Free fatty acids can be removed by chemical deacidification or physical deacidification.

(1) Chemical deacidification: Add lye to the caustic smelter to carry out acid-base neutralization reaction with free fatty acids, and finally produce soapstock to separate and remove.

(2) Physical deacidification: In the deodorization equipment, free fatty acids are separated out by steam.

- Decolorization process: remove the pigment in the crude oil and make it clearer and more transparent.

The decolorization section is carried out in the decolorization pot, the pigment and other impurities in the crude oil are removed by the adsorption of the clay, and then the waste clay is filtered out with a leaf filter to achieve the purpose of decolorization.

- Deodorization section: remove odorous substances in crude oil.

Under the high-temperature vacuum condition in the deodorization tank, steam heating is used to remove odorous substances in the oil and improve the quality of the refined oil.

After the above four stages of processing, the refined soybean oil has pure color and mellow taste, and all ingredients meet national standards. It can be sold directly on the market or provide raw materials for deep-processed products.

10TPD Complete Set of Soybean Oil Refining Plant

The above is the process flow of small soybean oil refining machine. If you want to seriously remove harmful impurities in crude oil, a set of soybean oil refining equipment is indispensable. Soybean oil refining equipment produced by ABC Machinery can truly help you achieve stable investment and high returns in terms of equipment material and refining efficiency. We can customize the equipment according to your production needs, welcome to leave a message for detailed consultation!

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!

Screw Oil Press

Screw Oil Press Small Oil Mill Plant

Small Oil Mill Plant Small Oil Refinery

Small Oil Refinery Automatic Oil Press

Automatic Oil Press Multifunction Oil Press

Multifunction Oil Press Hydraulic Oil Press

Hydraulic Oil Press

![[Presidential Visit] Zimbabwe 30 Tons/Day soybean oil plant for Extraction and Refinery Was Successfully Completed](/uploads/allimg/soybean-oil-plant-press-refine-business-lp.jpg)